Seamlessly joined: resistance welding electrodes for welding vehicle electrics

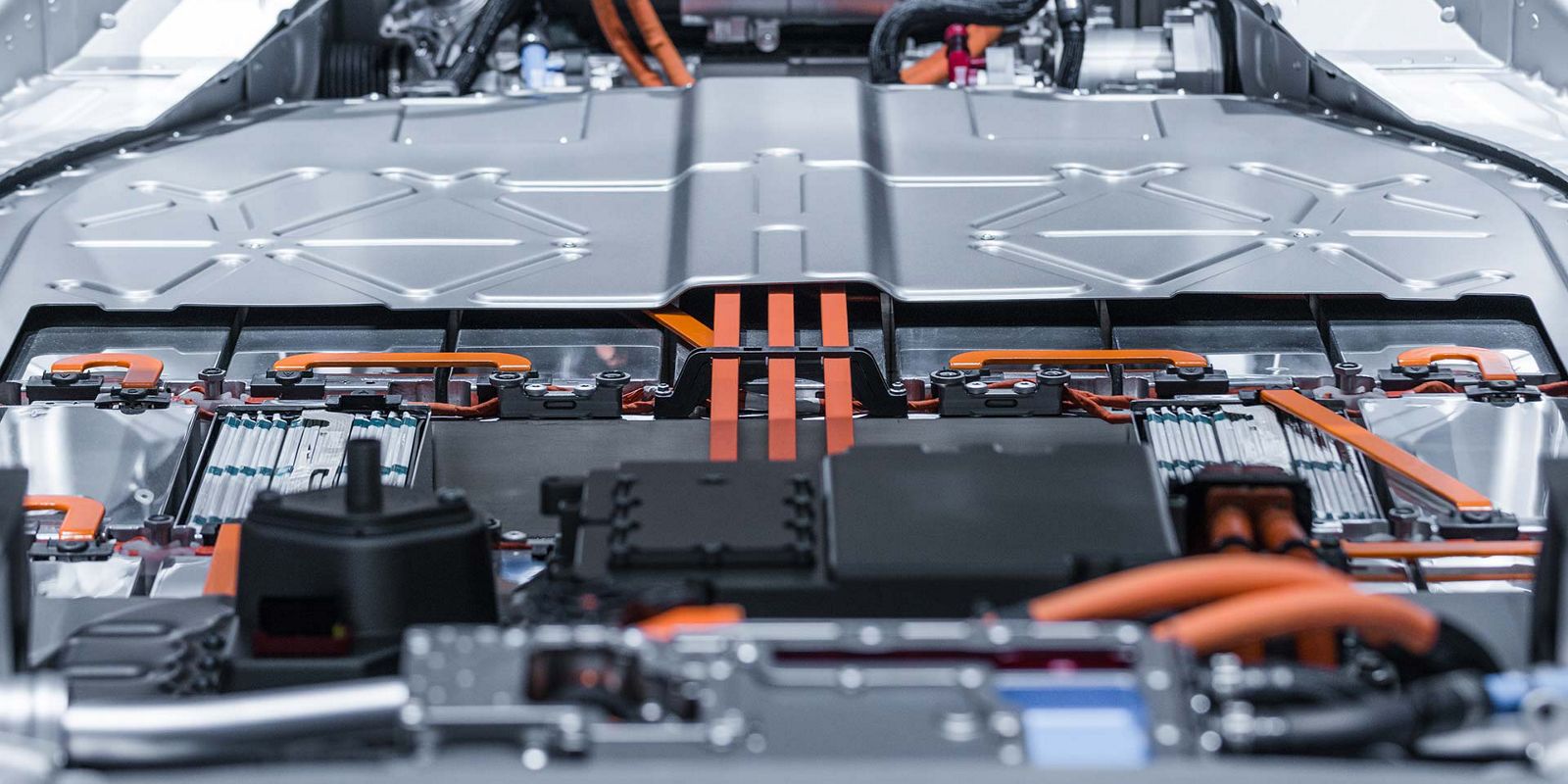

Molybdenum and tungsten play an important role in the automotive industry. Both of these materials and their alloys are used in numerous processes. They are also used for cabling welding and the complete vehicle electrics.

The individual components of the vehicle cabling are connected reliably together using resistance welding. Resistance welding electrodes made from our refractory metals and their alloys have good electrical conductivity and an excellent high-temperature resistance. For our back-cast electrodes, copper or CuCrZr is joined 100% with inserts made from our refractory metals. This seamless joining not only increases the electrode service life, but also productivity. Reproducible welding results are the basic prerequisite here.

The best part: using our back-cast electrodes, you can reduce the current being applied, which helps to reduce CO2. This not only has a positive effect on the environment, but it also lowers your energy costs at the same time.

You can rely on Plansee as a reliable partner with 100 years of experience in refractory metal processing. Due to our experience, we know how to work with difficult-to-process metals and still maintain the strictest tolerances. Your advantage: the highest product quality and absolute precision from prototypes to the finished product.

Your advantages at a glance:

Highest product quality

Sound application

knowledgePrototype

development

Learn more about our resistance welding electronics for vehicle electrics welding: