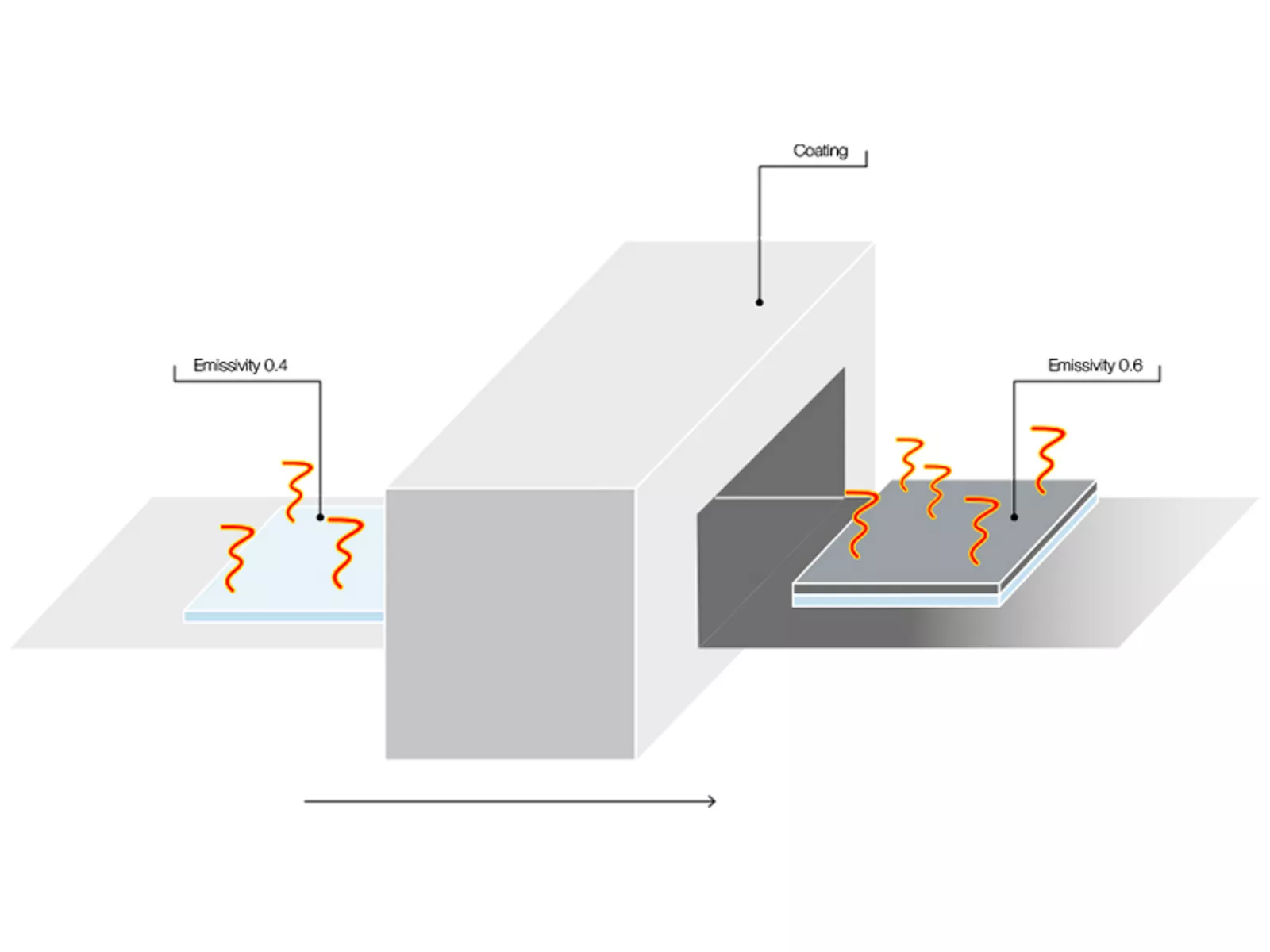

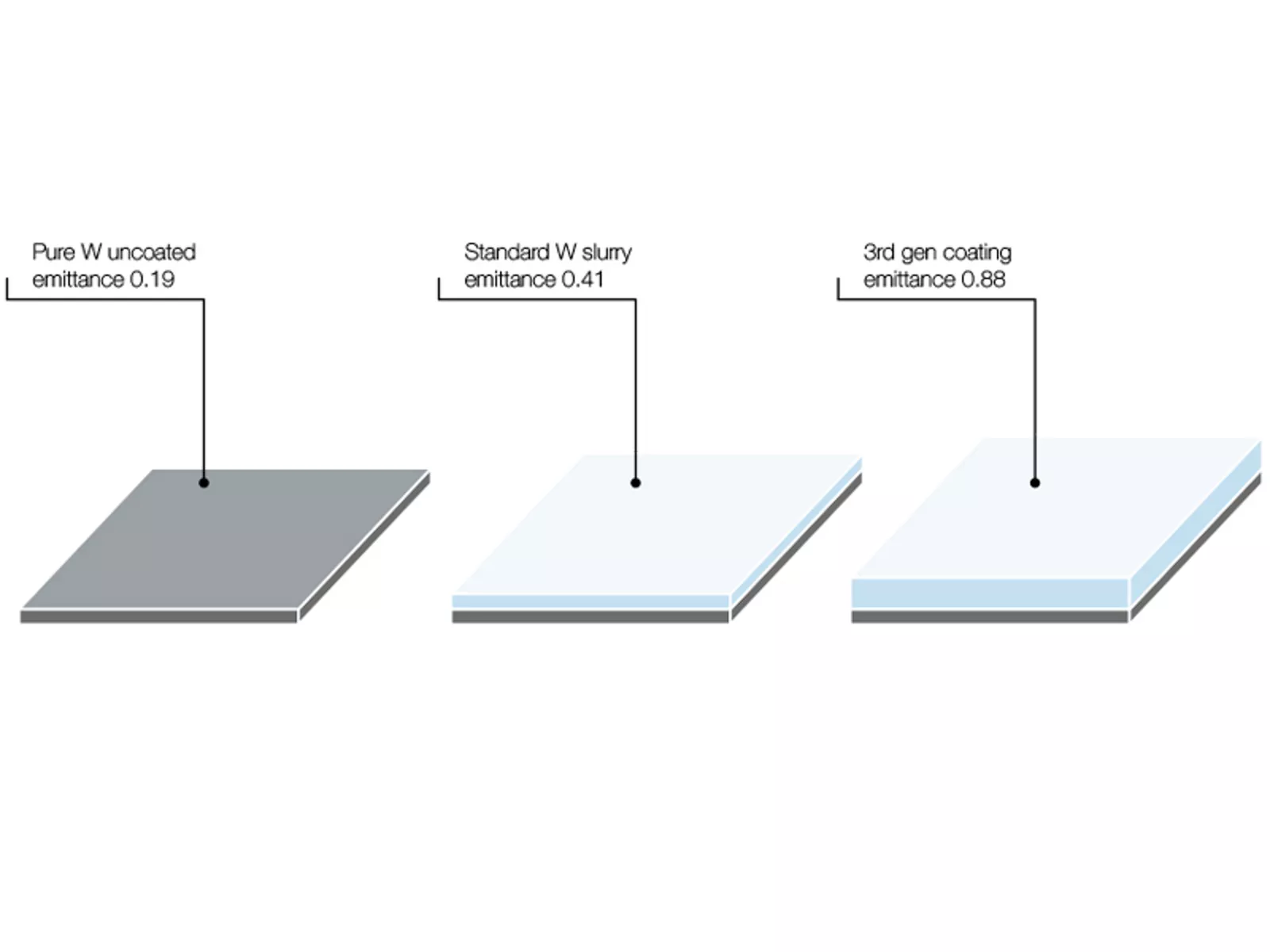

The heating elements in a MOCVD system are heated to 2000°C. These high temperatures make our molybdenum and tungsten high-performance materials indispensable for various shieldings, gas collectors, and heating elements. Plansee supplies over 50 different components for MOCVD. We are a recognized OEM for MOCVD systems as well as active in the spare parts market. We are also more than just a substitute for our customers because of our improved technical designs and patented coatings.

Customer-specific designs for a homogeneous temperature distribution

The semiconductor layer in an LED needs to be able to transmit light at approximately the same wavelength. An important prerequisite for this is homogeneous temperature distribution in the MOCVD system. Any deviation in the temperature profile will lead to a change in the color of the light being emitted later on. Our engineers use elaborate calculations to simulate the MOCVD process of the respective system with the help of the finite element method (FEM) to improve the design of our heating components. The new components increase temperature homogeneity in the reactor chamber. The customer profits from a higher yield per coating cycle, thus ensuring higher productivity.

We work together with our customers to develop customized designs for heating elements as well as other components for the MOCVD reactor.