Components for generating X-rays

X-ray technology is being used in more and more industries; in addition to medical technology, it is also employed in security technology, quality assurance (inspection), the food industry, and measurement technology. The requirements placed on the X-ray sources for these systems are varied and require the most diverse range of technical solutions.

We use our refractory materials to produce tailor-made X-ray anodes and components for all of these X-ray tubes, which satisfy the most stringent requirements in terms of quality and precision.

Your advantages at a glance:

REACH- and RoHS-compliant materials

Design optimizations by means of FEA

Tailored production procedures

100% product testing and tracing

Ready-to-install high-vacuum components

Management of the entire product life cycle

Take a look here at the process for generating radiation and subsequent collimation using a CT device. Plus, get an overview of our product portfolio:

Anodes for X-ray tubes

We provide full-metal rotating X-ray anodes and rotating X-ray anodes with a graphite body specially designed for X-ray tubes. These rotating X-ray anodes are manufactured from molybdenum alloys such as TZM, molybdenum-hafnium carbide (MHC), or molybdenum-niobium (MoNb) with focal tracks made of various tungsten-rhenium alloys. These rotating X-ray anodes can be combined with coatings and soldering solutions from our extensive technology portfolio.

We produce our stationary anodes that are back-cast with copper from tungsten, potassium-doped tungsten (WVM), or tungsten-rhenium (WRe). The perfect combination of tungsten and copper ensures excellent heat removal and guarantees a long service life of our components.

We also produce linear anodes for generating X-rays from TZM- or copper bodies with a soldered W or WRe focal track.

Our technologies and procedures for manufacturing anodes

- Metal and graphite anodes

- Integrated anode shaft (joining or manufacture by means of forging, soldering, or friction welding)

- Copper-back-cast stationary anodes

- Linear anodes with soldered focal track

- TiO2 or TiO2-Al2O3 layers for increased heat emissions

- Anti-dusting coating

- PM and VPS focal tracks (tungsten and tungsten-rhenium alloys)

Cathodes and components for X-ray tubes

X-ray radiation is produced by the deceleration of free electrons at the anode. The free electrons are generated via filaments or flat emitters. Plansee has specially doped non-sag tungsten and WVM materials and semifinished products for this purpose. Secondary electrode interceptors, which we produce from forged TZM bodies, are used to intercept scattered electrons. We use materials such as Mo and Ni for the cathode holders/arms and focusing heads. The cathode components can be soldered with the ceramic insulators (for the electrical connections) to form a single assembly in a single soldering step.

Our technologies and procedures for manufacturing our cathodes

- Precision laser- and EDM cutting

- Copper back-casting

- Soldering

- Electropolishing

- High-precision processing (milling, turning, grinding)

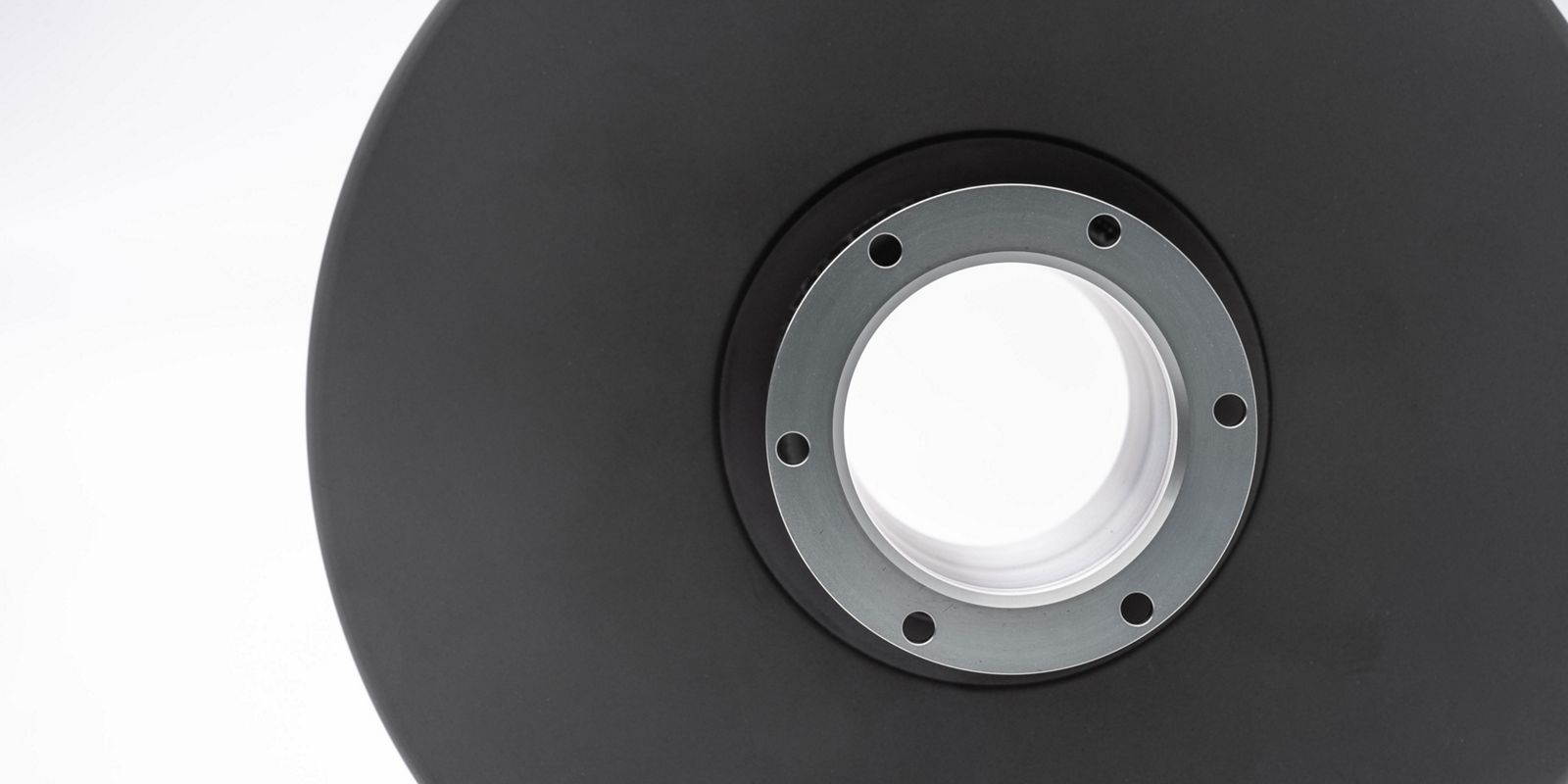

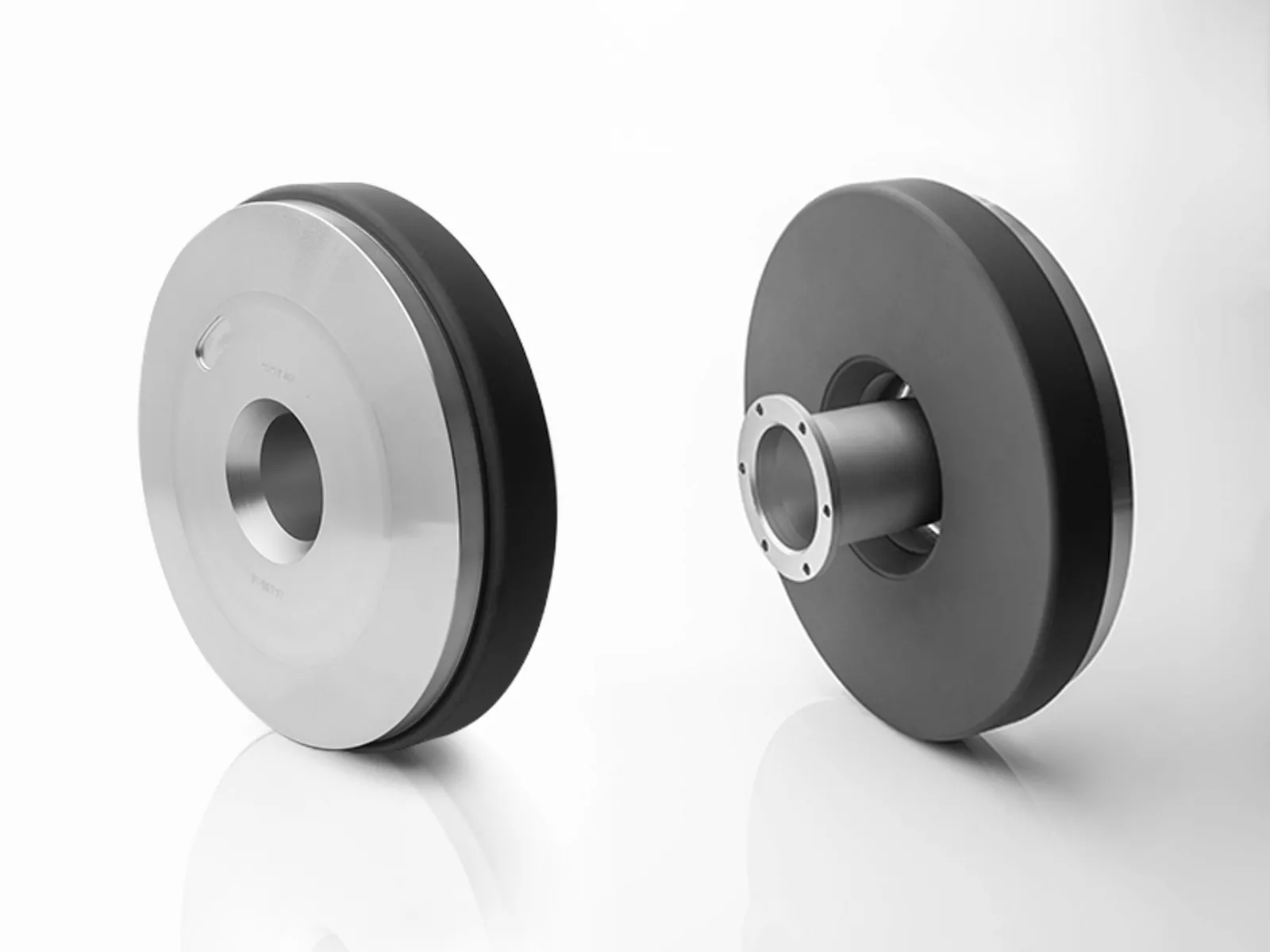

Drive components for X-ray tubes

We produce extremely robust drive components such as rotors, spiral groove bearing components, shafts, nuts, washers, and heat shields for high-resolution devices, from general X-rays through to computer tomography scanners.

Our drive components are made of molybdenum and tungsten as well as alloys and composites containing copper or noble metals.

We use various joining techniques for this.

Technologies and processes for manufacturing our drive components

- Copper back-casting for rotors with steel- or pure iron cores, for example

- Soldering, friction, and electron beam welding for rotors with TZM stems, nickel-steel flanges, and copper cylinders

- Ultra-high-precision processing of spiral groove bearing components (also known as liquid metal bearings)

- Various coatings such as PVD, VPS, CVD, and APS

Shieldings and filters for X-ray tubes

During the generation of X-rays, our materials reduce environmentally harmful radiation to a minimum. Shieldings and components made of refractory metals such as tungsten, molybdenum, and tungsten heavy-metal alloys (DENSIMET®) make sure the radiation only occurs where it is actually needed.

Our materials satisfy RoHS criteria (Restriction of Hazardous Substances) and represent an alternative to components containing lead for numerous medical technology manufacturers.

Our technologies and procedures for manufacturing shieldings

- Precision laser- and EDM cutting

- Punching

- Rolling, bending, and deep drawing

- Electron beam welding

- High-precision processing

- Selective laser melting (SLM) as an additive manufacturing technology for Mo and W

Purest materials – highest quality

The uncompromising quality and reliability of our products are essential to us. We therefore only use the purest materials and alloys for our products. From raw material supply all the way through to the finished product, we closely monitor every step in the production process. We have combined all the expertise for this under one roof. This guarantees transparent production and 100% traceability of the products for our customers.

We always inspect and package all components carefully prior to delivery. We package particularly sensitive products individually according to specific customer requirements. We even deliver high-vacuum components ready to install.