Advantages when machining steel and carbides

We have a committed team of tungsten heavy metal alloy researchers and developers who ensure the high quality of our Sparkal® electrodes. We are continually optimizing our products in close cooperation with our customers. The results are impressive:

High wear resistance

Due to the high melting point of tungsten (3420°C), WCu electrodes have a considerably longer service life than copper or graphite electrodes, in particular, for small electrodes which have undergone complex machining. As the production costs of complex electrodes often far exceed the pure material costs, the use of Sparkal® represents a considerable cost saving due to the extended electrode service life.

Extremely sharp contours

The low wear levels of SPARKAL® EDM electrodes make it possible to focus the arc precisely and achieve greater geometrical accuracy in the workpiece than is possible when using pure Cu or graphite electrodes. You can machine your products to a high level of precision and achieve low machining tolerances.

High surface quality

The use of Sparkal® during the finishing process results in outstanding surface quality and, in particular, eliminates the need for circular electrode movements. This is possible thanks to the fine, uniform grain and freedom from pores offered by Sparkal®.

Very good machinability

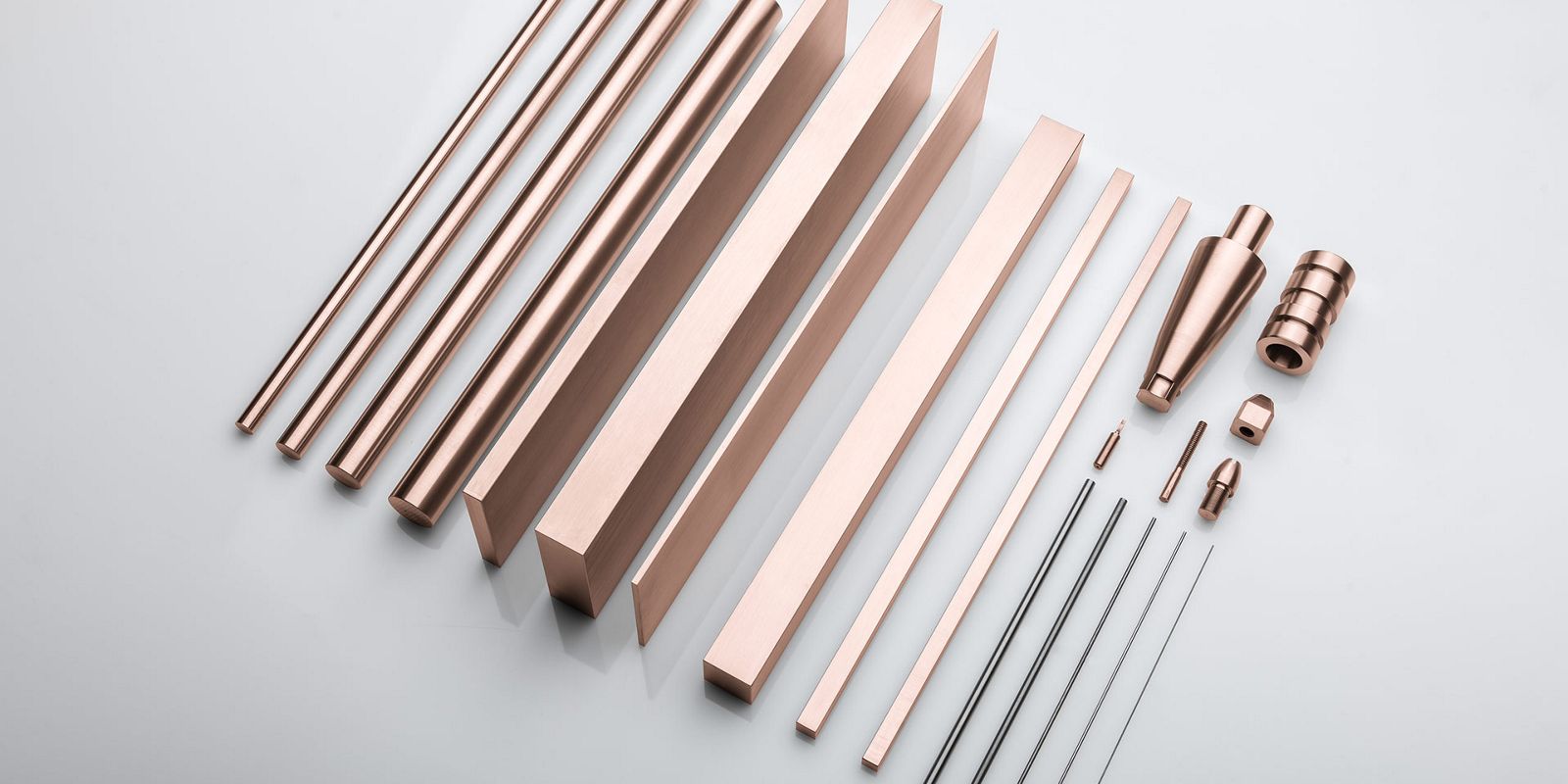

The considerably greater modulus of elasticity and greater hardness offered by Sparkal® lead to exceptionally good machinability. Compared to copper, there is practically no material deformation and the level of burr formation is negligible. Unlike graphite, there is no material chipping and the geometrical accuracy of the electrodes is improved. Thanks to these material properties, it is possible to manufacture Sparkal® rods and tubes in extremely small diameters and particularly long lengths.

Improved environmental and working conditions

Machining with graphite electrodes requires the use of special extraction systems to remove dust, prevent graphite-smeared floors, and keep the air clean. In contrast, machining with Sparkal® does not require any additional equipment.