Spare parts specialist for over 100 systems

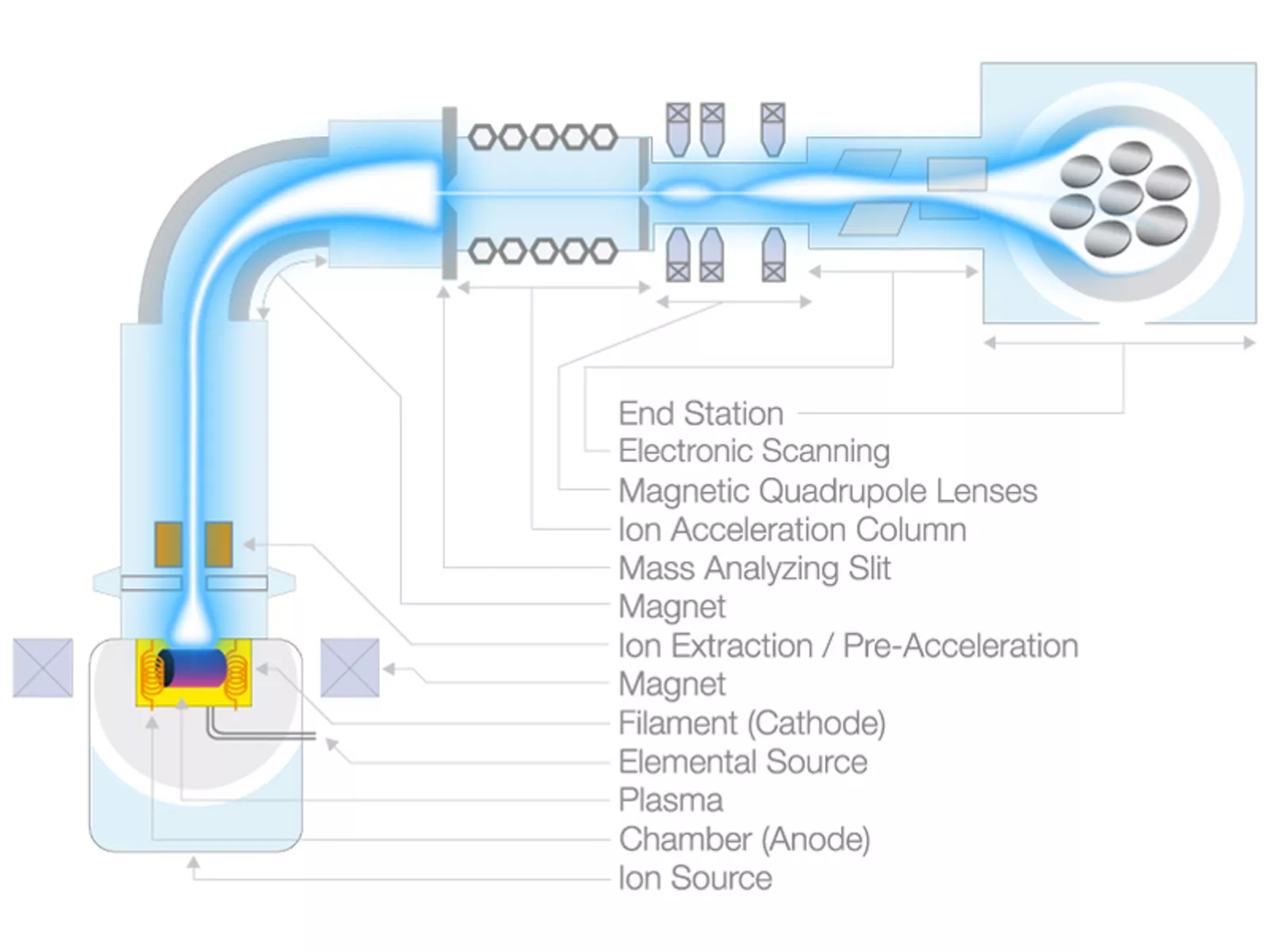

Whether an old model or next generation, medium or high current: we know them all and naturally have the right spare parts for you in our range. Would you like to get more out of your ion implanter? Get in touch. Even if you can't find your system on the list.

AIBT: istar

Applied Materials: 9000, 9200, 9200xR, 9500, 9500xR, Quantum, Quantum I, Quantum II, Quantum III, Quantum X, Quantum X+, Quantum xR, xR, xR/Leap, xR120, xR200, xR80

Varian Semiconductor Equipment (now Applied Materials): VIISta Trident, PLAD, VIISta HCS, VIISta HCP +/I, VIISta 80, E1000, VIISion 200, VIISion 200+, VIISion 80+, VIISta HC, 120-10, 120XP, 160XP, 180XP, 80XP, VIISta 3000, Genus, Kestrel, VIISta 810 XE/XER, VIISta 900 XPT, VIISion, E220, E500, VIISta 810, VIISta 810 XE, VIISta 900, VIISta 900XP, 300D, 300XP, 350D

Axcelis: GSD HC (200/200E/200E2), HC3, Ultra, Eterna, GSD 100, GSD 160A, GSD 200E, GSD 200E^2, GSD HC, GSD HC3, GSD III, GSD III LE, GSD LED, NV GSD, NV 10-160, NV 10-180, NV 10-80, Optima HD, ULE, Ultra, GSD HE, GSD VHE, GSD HE, GSD HE3, GSD VHE, Optima XE, Paradigm XE, NV 3206/3204, NV 6200, NV 8200, NV 8250, Optima MD

Nissin: NH80, PR80, Exceed 3000, CLARIS, EXCEED2000A/2000AH, EXCEED2300AV, EXCEED3000AH, EXCEED9600A, NH20, NH45

SEN: NV-GSD-160A, NV-GSD-80A, NV-GSDIII, NV-GSDIII-180, SD, NV-GSDIII-90E, NV-GSDIII-LE, NV-GSDIII-LE, V-GSD-HC, LEX, LEX3, SHX, NV-GSD-HE, NV-GSD-HE3, MC3MC3-II, NV-MC3

Ulvac: IH-860, IDZ-7000, IDZ-8001, IDZ-9001, IM-200, IW-630

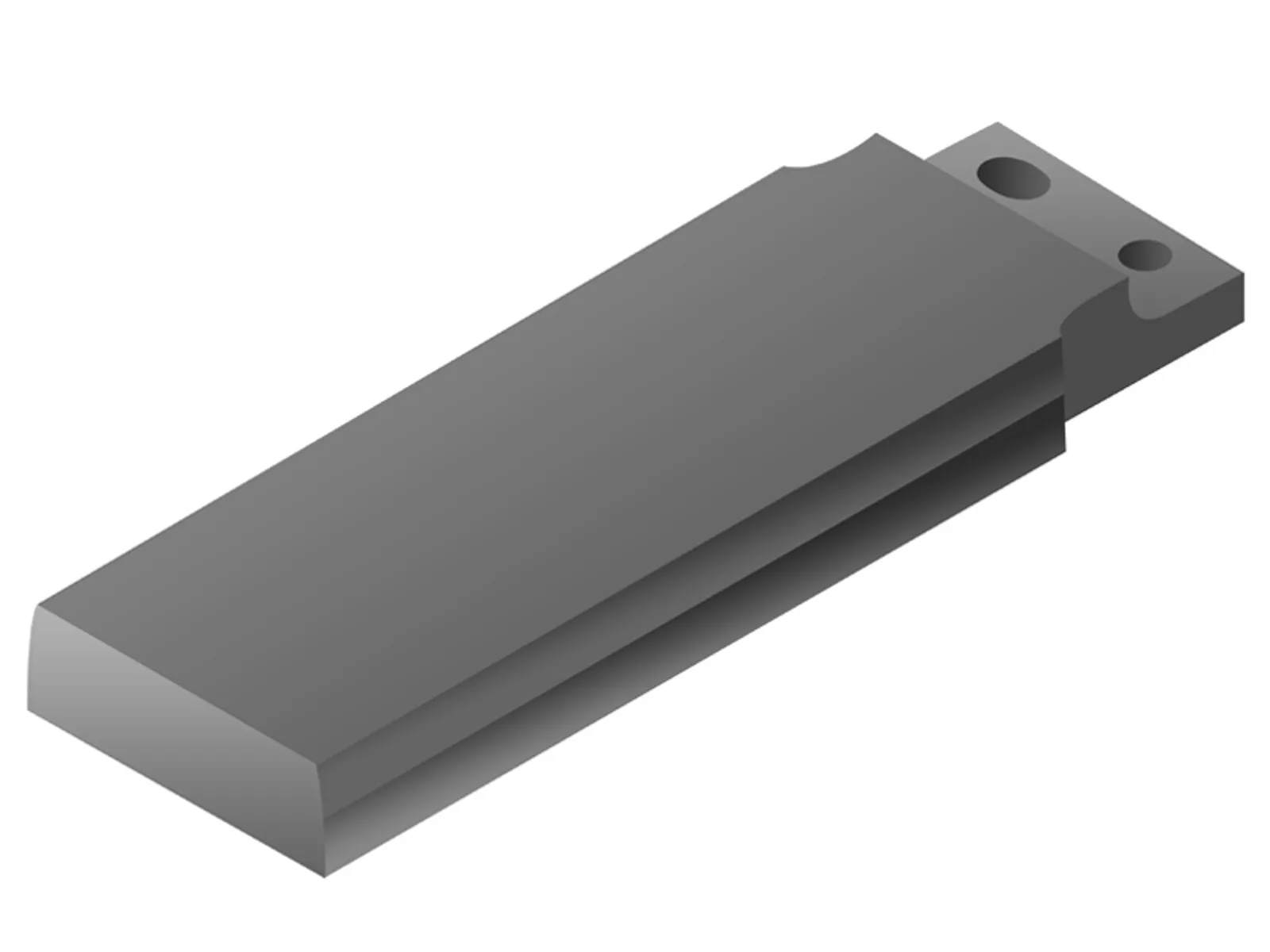

Try out our online product catalog. There you will find several of our OEM-quality implanter spare parts as well as components designed by Plansee for improve service life and easy handling. Our product catalog offers additional features for existing customers, where you can view your orders, delivery status, and invoices.

Contact us at ionimplantation(at)plansee.com for your personal login.