Reliable welding aids for your lamp production

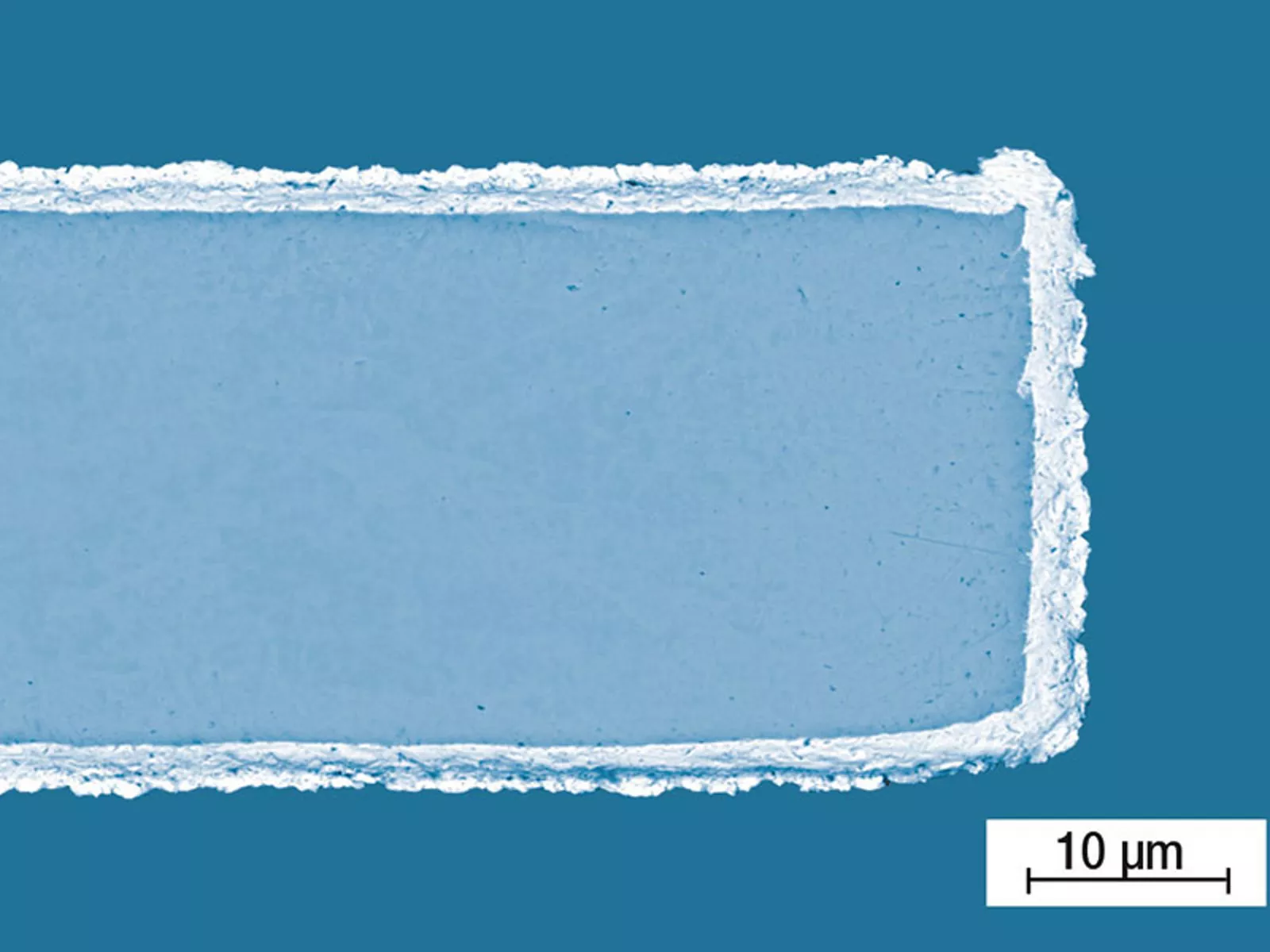

The tungsten electrode must be connected to the ESS ribbon inside the lamp. Tungsten electrodes and MY ESS ribbons both have a high thermal and electrical conductivity as well as high melting points. These properties make welding more difficult. To ensure a reliable connection between both components, we supply thin tantalum ribbons or platinum-coated molybdenum ribbons. They are inserted between the ESS ribbon and the tungsten electrode, making a reliable welded joint possible.

Our molybdenum and tantalum ribbons also ensure the best welding results in the production of halogen lamps. In this case, the electrically conductive ESS ribbon and tungsten coil are joined using resistance welding.

The result is a reproducible process and low scrap rates.