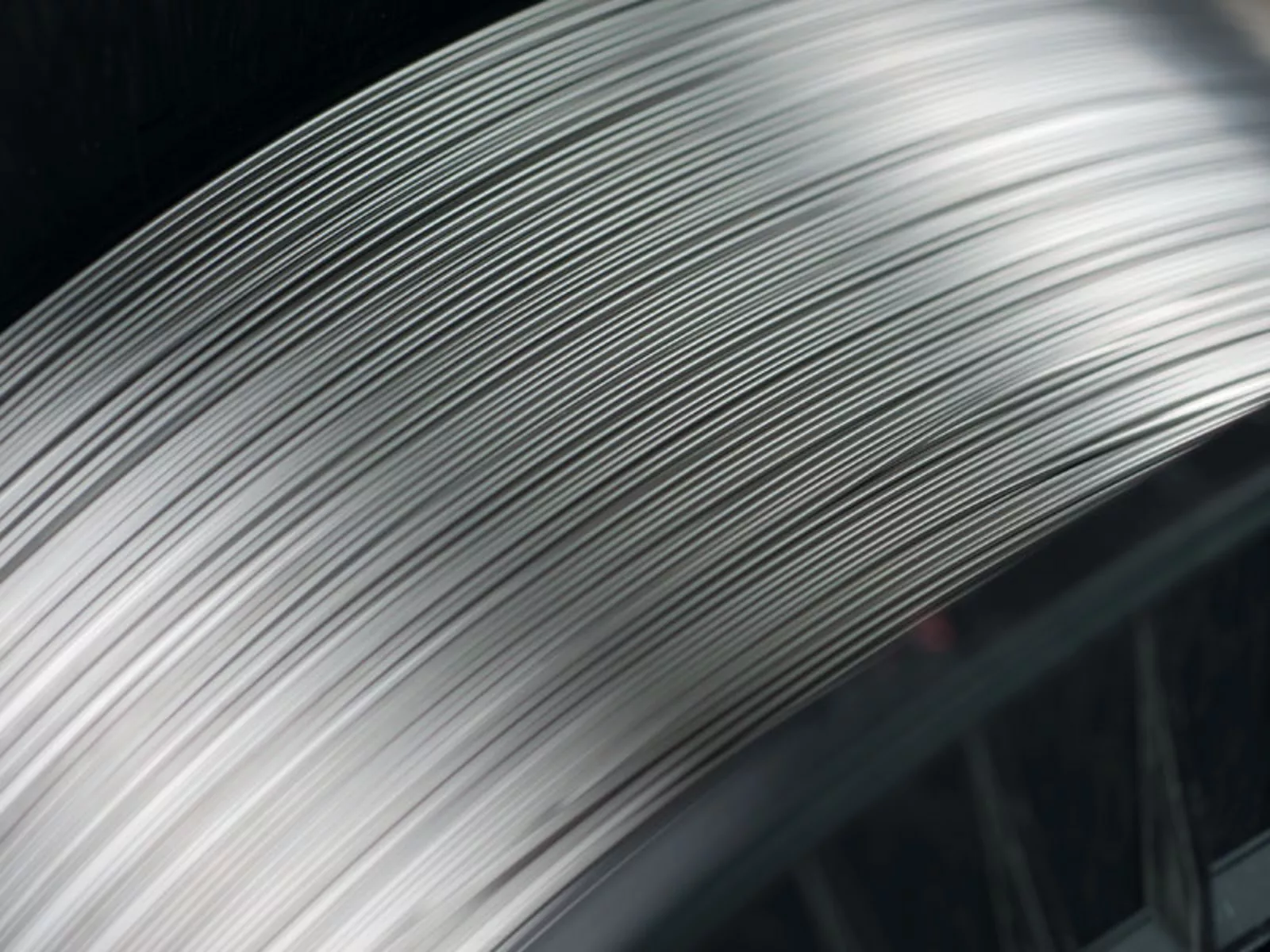

Wire as fine as 10 µm

We don't just supply redraw wires made of molybdenum and tungsten, but also fine wires with a diameter as fine as 10 µm.

Our fine wires are used in applications such as medical technology.

Our wires made of molybdenum and tungstens are required anywhere unique material properties are in demand whether in lamps, coating systems, satellites, or medical technology.

Learn more about the special properties of our materials made of refractory metals in our Materials section. There you will find information regarding the further processing of our semi-finished products: To our materials

We produce the highest quality wires made of refractory metals in our ultra-modern production facilities. Our equipment enables us to offer a wide range of products, giving you diverse possibilities. We can also manufacture large quantities without any problems.

You can order standard dimensions directly from stock: Plansee Online Shop

High surface quality

Special doping depending on the application

Meets the strictest tolerances

Comprehensive final check for guaranteed quality

High production capacities and flexible manufacturing

Individual dimensions upon request

Download our product specifications:

We don't just supply redraw wires made of molybdenum and tungsten, but also fine wires with a diameter as fine as 10 µm.

Our fine wires are used in applications such as medical technology.

Fine tungsten wire is used as filaments in halogen lamps, fluorescent lamps, and incandescent lamps. Our wire used in halogen lamps in car headlights is highlighted by its freedom from fissures, very high surface quality, very strict diametrical tolerance, and stable mechanical properties.

Our fine tungsten wires are nearly invisible as they heat the windshields of modern automobiles. In this application, the low tolerance ranges required for electrical resistance and the high surface quality of our wires are particularly important.

Among its other applications, fine molybdenum wire is used as support wire for incandescent lamps and core wire for filament manufacturing.

Plansee has been making W and Mo wires since 1921. Thanks to our capacities, we can manufacture wires in large quantities without difficulty. Our one hundred years of experience and our state-of-the-art systems enable us to guarantee you the best quality for every wire.

Whether graphitated, pickled, or electropolished, we can adapt our products precisely to your specific application.

We can provide the following dimensions:

| Material | Diameter in mm |

| Mo | 0.015 - 3.17 |

| ML | 0.200 - 3.17 |

| Mo-ILQ | 0.015 - 3.17 |

| W | 0.025 - 1.50 |

| WL05 | 0.010 - 1.50 |

| WVM | 0.050 - 1.50 |

| WRe05, WRe26 | 0.400 - 1.50 |

We would be happy to produce tailor-made wires for you as well as help you find innovative solutions for your specific requirements.

We also have standard dimensions in various surfaces available from stock in our Plansee online shop.

You can select from a number of materials to find just the right one for your requirements:

Mo

Molybdenum has versatile applications. It is creep-resistant, has a high rigidity, low thermal expansion, and a high thermal conductivity. It is also corrosion-resistant compared to many other metal and glass melts.

ML

With a lanthanum oxide content of 0.3% by weight, this stabilized molybdenum has a high creep resistance and high recrystallization temperature.

Mo-ILQ

Mo-ILQ is a microdoped molybdenum alloy with a lanthanum oxide content of only 0.03% by weight whose dopant content was specially adapted. Compared to ML, Mo-ILQ is more suitable for forming and therefore easier to process.

W

Tungsten has the highest melting point of all metals, is creep-resistant, has a good electrical conductivity, high rigidity, and low thermal expansion.

WVM

Potassium-doped tungsten with a stacked structure that ensures increased dimensional stability at high temperatures.

WRe05, WRe26

We alloy our tungsten with rhenium to obtain greater ductility and a lower brittle-to-ductile transition temperature. In addition, tungsten-rhenium also has a higher recrystallization temperature and better creep resistance.

We do everything ourselves when it comes to the production of our wires. From raw material to the final product, including the development of new materials. This is how we guarantee the highest quality for our wires.

Short delivery times and clearly presented price scales – it's not just wires, we also have sheets, rods, ribbons as well as other products made out of molybdenum, tungsten, and tantalum available for you in configurable dimensions in our Plansee online shop .