Highest precision and accuracy: components for surgery and cardiology

The devices used in the areas of surgery and cardiology must conform to the strictest requirements. This is because they are not just used to examine internal organs, but also for vitally important surgical procedures such as bypass operations. When you are treating people, you have to satisfy the highest standards. Our components made of molybdenum and tungsten as well as their alloys meet these requirements. They are very well tolerated by the human body and are characterized by excellent properties such as strength, surface quality, and resistance.

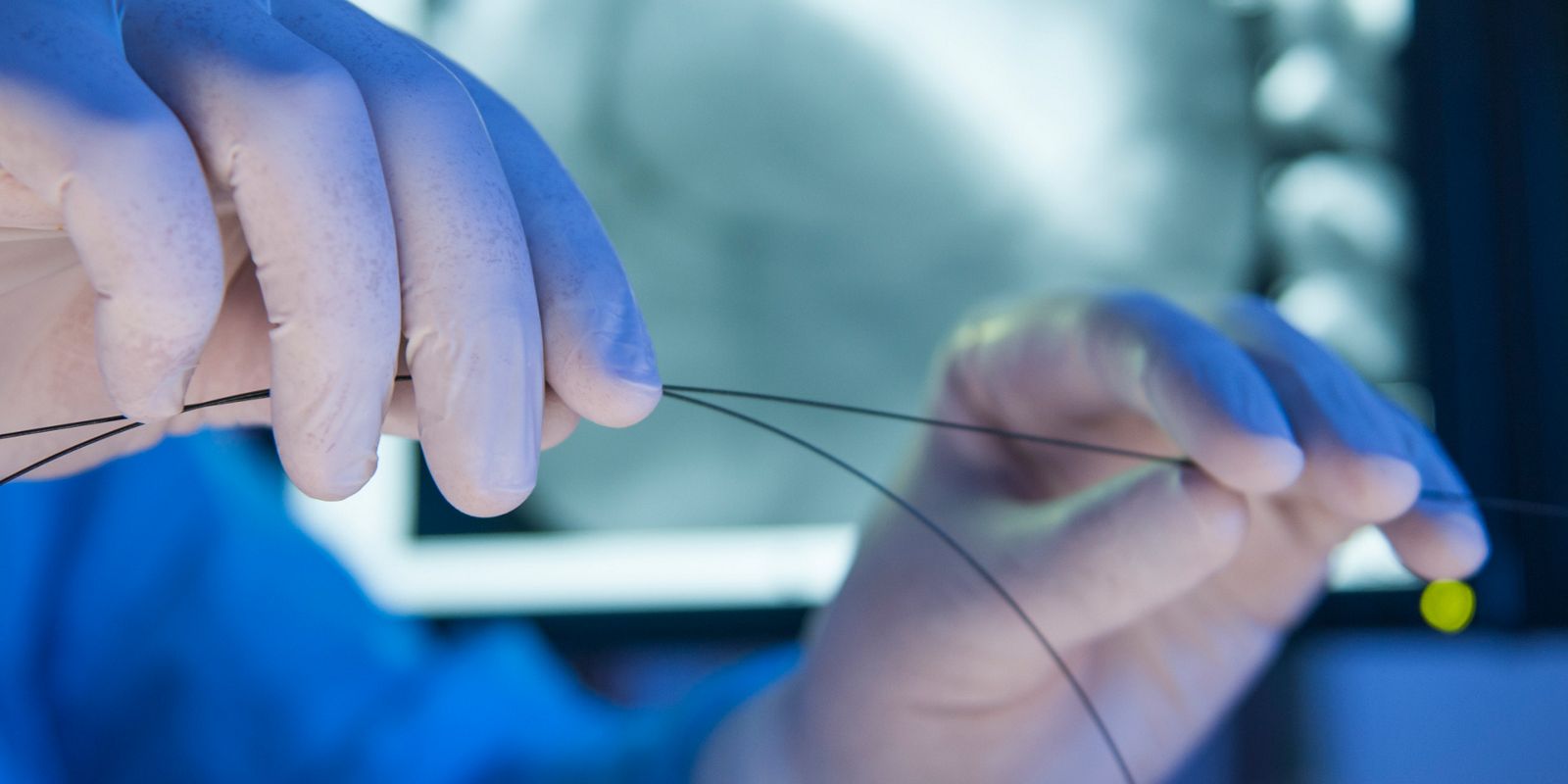

We supply various products for these medical fields from ultrafine wires to tubes, blanks, and rods. On top of this we offer targets made of tantalum and niobium, which are required for biocompatible coatings on medical implants. Naturally, our products conform to the very highest quality standards.

With our decades of experience in the area of medical technology, we have extensive technological know-how. Our production chain starts with the reduction of ultrapure oxide to metal powder. This is how we can achieve the high material purity of our products. We manufacture compact, metal parts from porous powder blanks. Using special forming processes and mechanical processing steps as well as modern coating and joining technologies, we turn these into complex components with a maximum density and the highest quality. That is why medical device manufacturers have been relying on our products made from refractory metals for many years now. You profit from the decades of technical knowledge of our scientists and engineers, who will work closely together with you on your individual solutions.

Your advantages at a glance

Sound application knowledge

Innovative partner for individual solutions

Products with the highest quality and precision

Biocompatible materials with excellent properties

REACH- and RoHS-compliant materials

High delivery reliability via a global production network

Learn more about our products for surgery and cardiology: