We would be happy to provide you other specifications upon request.

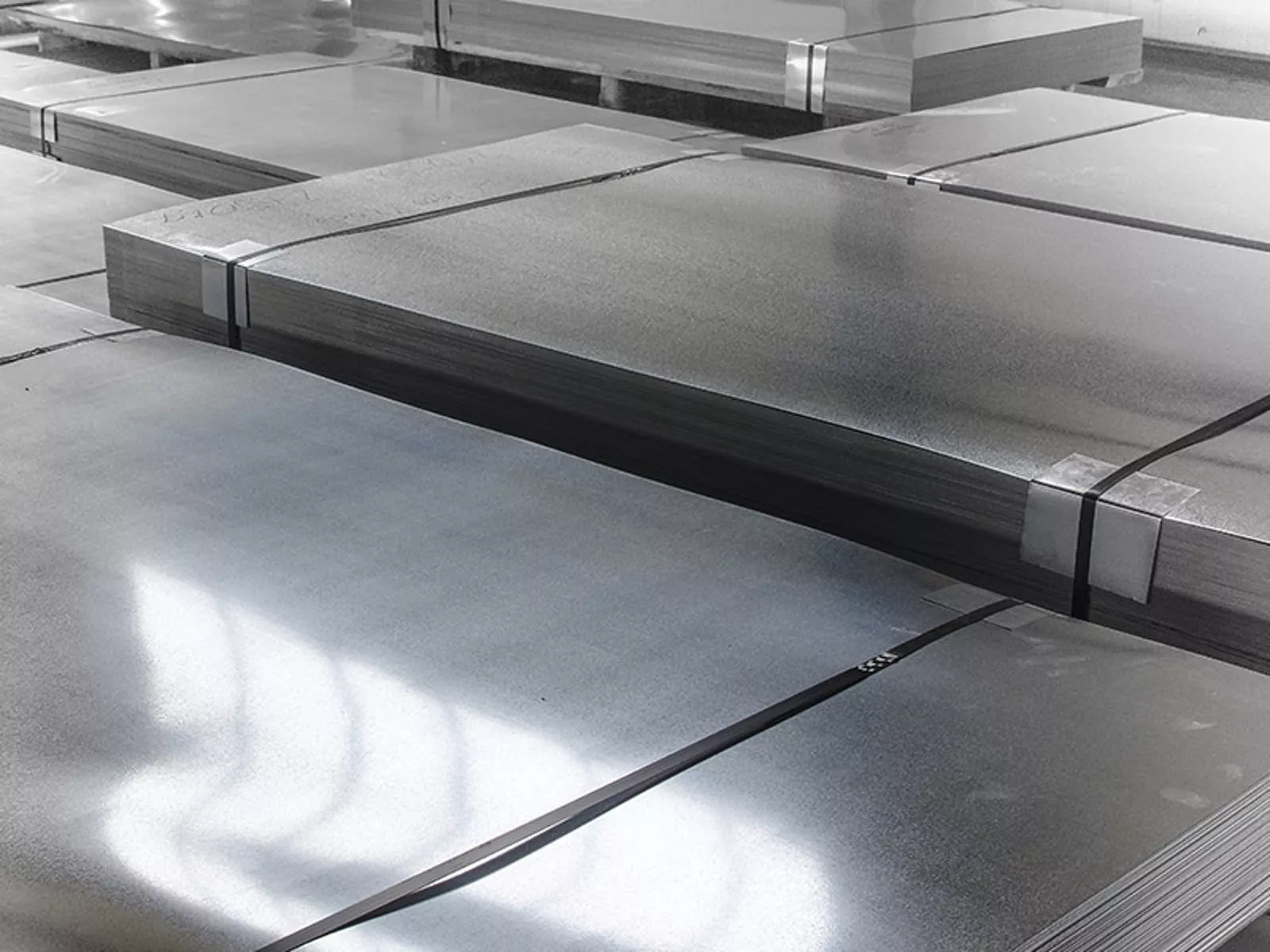

Sheets made of molybdenum, tungsten, tantalum, and niobium

Our sheets made of molybdenum, tungsten, tantalum, and niobium are used wherever unique material properties are required, be it furnace construction, medical technology, or as a precursor material for the further processing of semiconductor components.

Learn more about the special properties of our materials made of refractory metals in our Materials section. There you will find information regarding the further processing of our semi-finished products: To our materials

We produce the world's largest, high-quality sheets made of refractory metals in our ultra-modern hot and cold rolling mills. Our equipment enables us to offer a wide range of products for flat semi-finished goods, giving you diverse possibilities. We can also manufacture large quantities without any problems.

You can order standard dimensions with various surfaces directly from stock: Plansee online shop

Your advantages at a glance:

High purity

> 99.97%Observe the strictest product tolerances

High surface quality

Good re-usability

Wide-ranging product portfolio

Standard products from stock, individual dimensions upon request

Download our product specifications:

Dimensions and surface qualities

Thanks to the large-scale capacities of our production facilities, we can offer you a wide range of products in large quantities. Whether shiny, polished, or pickled – we have the right surface in the desired dimension for your application.

We can provide the following dimensions:

Material |

Thickness in mm |

Mo |

0.05 - 50.00 |

Mo-UHP |

Upon request |

TZM |

0.30 - 50.00 |

MLR |

1.00 - 50.00 |

MLS |

0.20 - 1.00 |

W |

0.025 - 20.00 |

WVM |

0.05 - 5.00 |

WL10 |

Upon request |

TaS |

Upon request |

TaM |

0.10 - 40.00 |

Nb |

Upon request |

We would be happy to produce tailor-made sheets for you as well as help you find innovative solutions for your specific requirements. In addition to this, we also have numerous, standard dimensions in various materials and surface qualities available from stock in our Plansee online shop.

The optimal material for your application

You can select from a number of materials to find just the right one for your requirements:

Mo

Molybdenum has versatile applications. It is creep-resistant, has a high rigidity, low thermal expansion, and a high thermal conductivity. It is also corrosion-resistant compared to many other metal and glass melts.

TZM

Titanium-zircon-molybdenum. This is a solid solution- and particle-reinforced molybdenum alloy with very high strength even at high temperatures. It has a higher recrystallization temperature and creep resistance than pure Mo.

MLR

With a lanthanum oxide content of 0.7% by weight, this stabilized molybdenum has a high creep resistance and high recrystallization temperature. It is supplied in a recrystallized version.

MLS

With a lanthanum oxide content of 0.7% by weight, this stabilized molybdenum has a high creep resistance and high recrystallization temperature. It is supplied in a stress relieved version to make further processing easier.

W

Tungsten has the highest melting point of all metals, is creep-resistant, has a good electrical conductivity, high rigidity, and low thermal expansion.

WVM

Potassium-doped tungsten with a stacked structure that ensures increased dimensional stability at high temperatures.

WL10

With a lanthanum oxide content of 1% by weight, this stabilized tungsten has a high creep resistance, high-temperature stability, high recrystallization temperature, and a lower electron work function compared to pure tungsten.

TaS

Tantalum in sintering quality with a high chemical resistance and good formability even below room temperature. Extremely fine-grained structure that has advantages for many deep-drawing applications.

TaM

Tantalum in melting quality with a high chemical resistance and good formability. Just like TaS, TaM is also particularly corrosion-resistant.

Nb

Niobium in melting quality with a high chemical resistance but significantly lower density than tantalum.

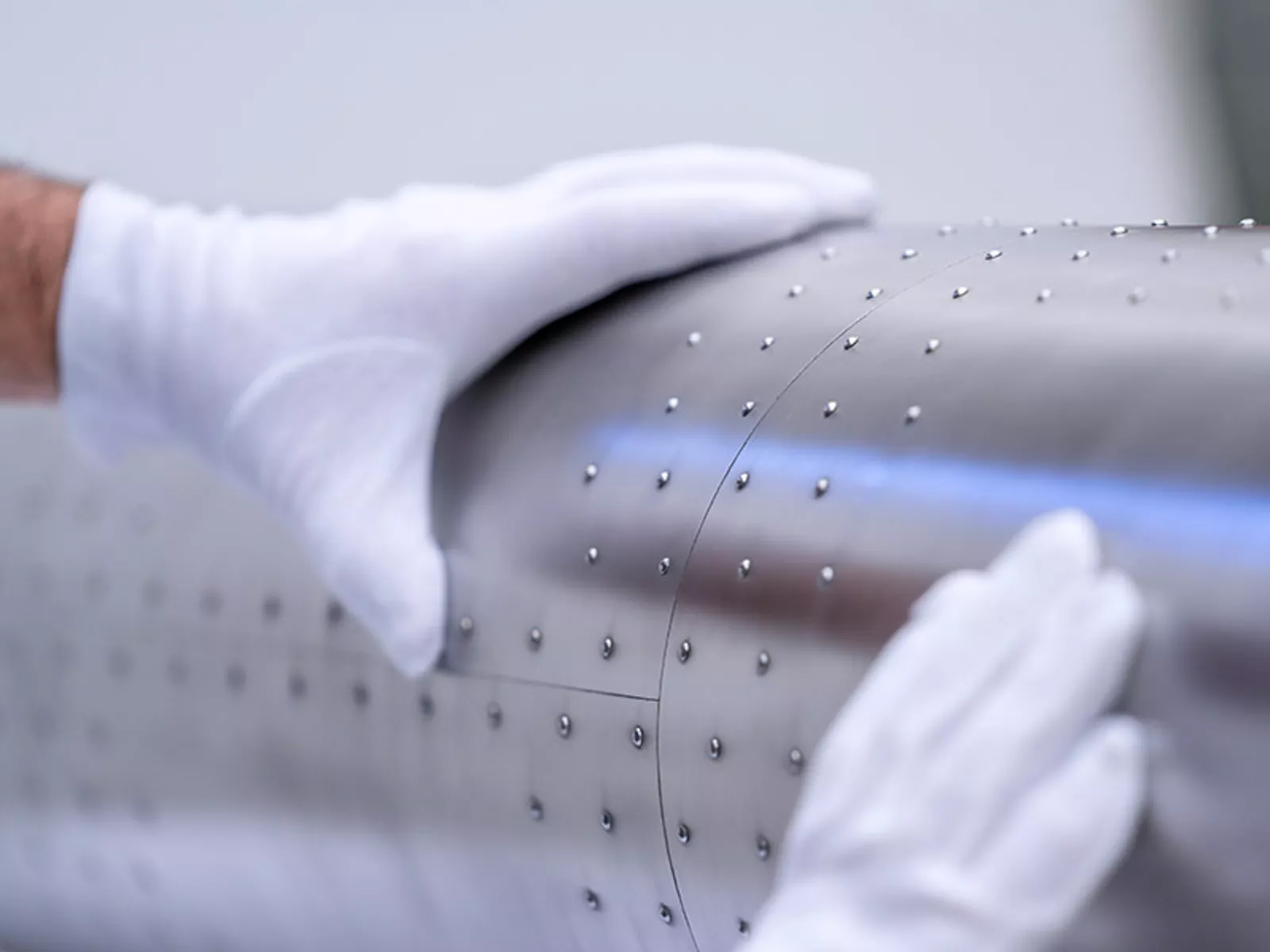

Our technologies and processes for sheet manufacturing

- The highest purity is ensured via automatic powder handling and process control that is continually being upgraded in the critical process steps powder production, pressing, and sintering

- Equipment from our hot and cold rolling mills with modern thickness control systems

- Highly dynamic, hydraulic gap control for maintaining the strictest product tolerances

- Automatic handling in critical process steps for sheet and ribbon production ensures high surface qualities

- Optimized process chain throughout the entire production process from powder to completed semi-finished product enables excellent mechanical properties such as good re-usability

In addition, we also have years of experience and the required skill for processing our semi-finished products into finished products. For example, we produce complex mounting parts such as hot zones for high-temperature furnaces.

Everything from a single source – from the powder to the finished sheet

We do everything ourselves when it comes to the production of our sheets. From raw material to the final product, including the development of new materials. This is how we guarantee the highest quality for our sheets.

Tungsten and tantalum from conflict-free sources

Tungsten and tantalum are partially mined in regions that are considered conflict and high-risk areas and are therefore classified as "conflict minerals." As a company aware of its responsibilities, we take particular care when sourcing raw materials.

Based on a wide range of measures such as the RMAP Recognition Certificate, we ensure that we do not source or use any raw materials from socially, ethically, or ecologically questionable sources.

Please see our company section for more about how we take our responsibility seriously and which certifications we have:

Short delivery times and clearly presented price scales – it's not just sheets, we also have rods, wires as well as products made out of molybdenum, tungsten, and tantalum available for you in configurable dimensions in our Plansee online shop.