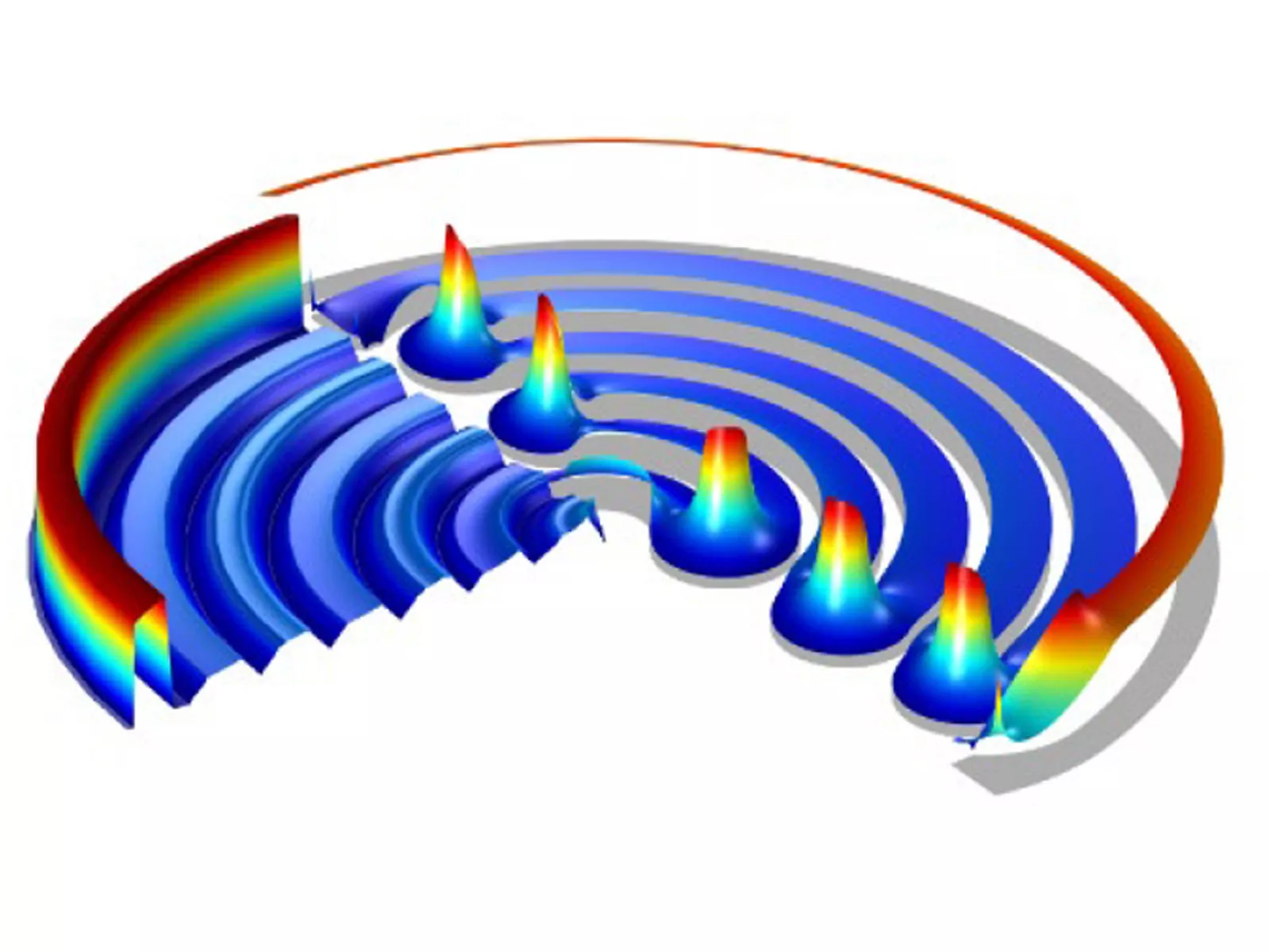

Our sound knowledge of materials forms the basis for our daily activities. Our experts are continually enhancing the properties of molybdenum, tungsten, tantalum and tungsten composites to increase their performance limits even further. We know exactly how the materials behave and what they are capable of, and can therefore create even highly complex products. More than 100 research and development experts at our locations in Austria, Germany, France and China are working on a daily basis to optimize the behavior of our materials in manufacturing and application processes. They examine mechanical, chemical, and physical behavior in our in-house laboratories and test the findings by means of specific trials in collaboration with customers. This means that we can continually produce new products and technologies.