Our sputtering targets and arcing cathodes for hard coating help to ensure wear protection and a long service life for a wide range of components. The highest material purity and optimal microstructures are basic prerequisites for us.

Durable and reliable: components for plant construction and toolmaking

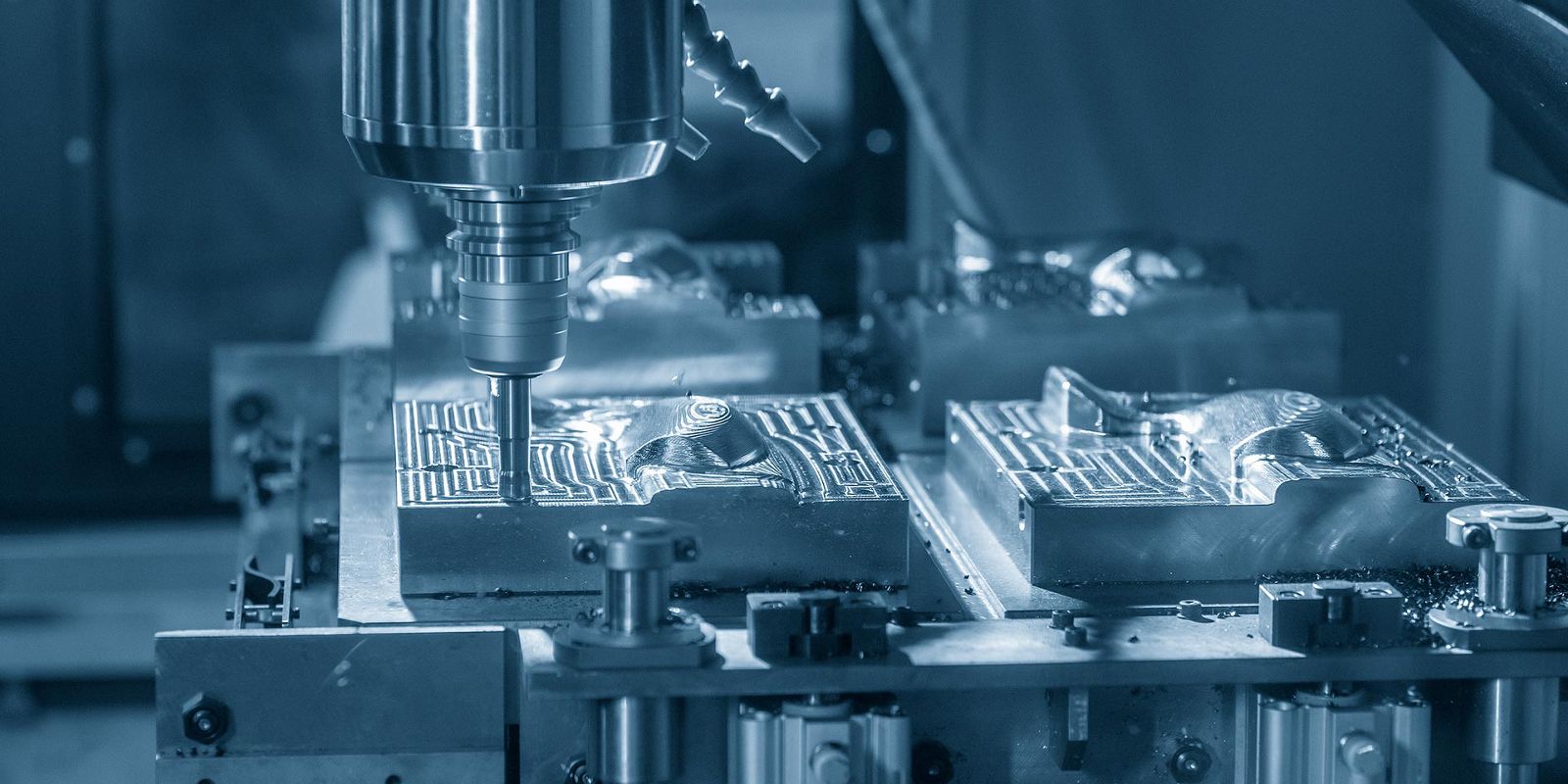

Our components made from molybdenum and tungsten are indispensable for plant construction and toolmaking. Especially wherever high-performance, durable, and long-lasting components are in demand. Our materials have unique mechanical and chemical properties: a very high melting point, low thermal expansion, and a high heat conductivity. That's why our components can stand up to even the harshest operating conditions.

Your advantages at a glance:

Sound application

knowledgeReliable partner

Highest precision

Development

collaborationSupply chain collaboration

Learn more about our products for plant construction and toolmaking:

From powder to the final product

One thing is certain: at Plansee we do everything in-house, from metal powder to finished product. Our production chain starts with the reduction of ultrapure oxide to metal powder. This is the only way that we can guarantee the high material purity of our products. We manufacture compact, metal parts from porous powder blanks. We operate the latest facilities for forming, processing, and coating. But it's our employees who make the real difference. They certainly know their way around difficult-to-process metals due to their decades of experience. Your advantage: the highest product quality and absolute precision. Our materials scientists and engineers will work together with you to find innovative and customized solutions for your application.