Our heating conductors are available as:

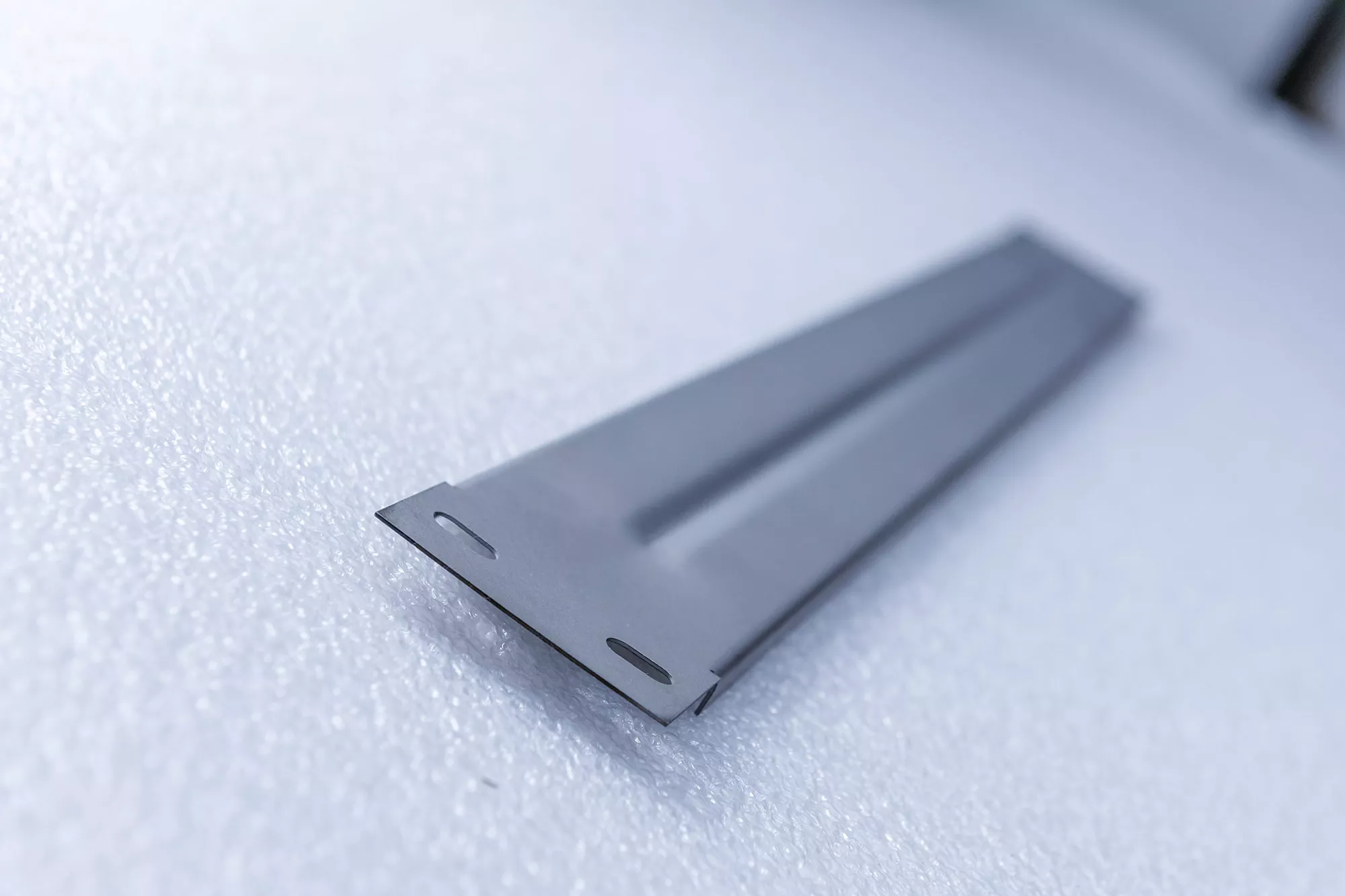

- Sheets

- Rods

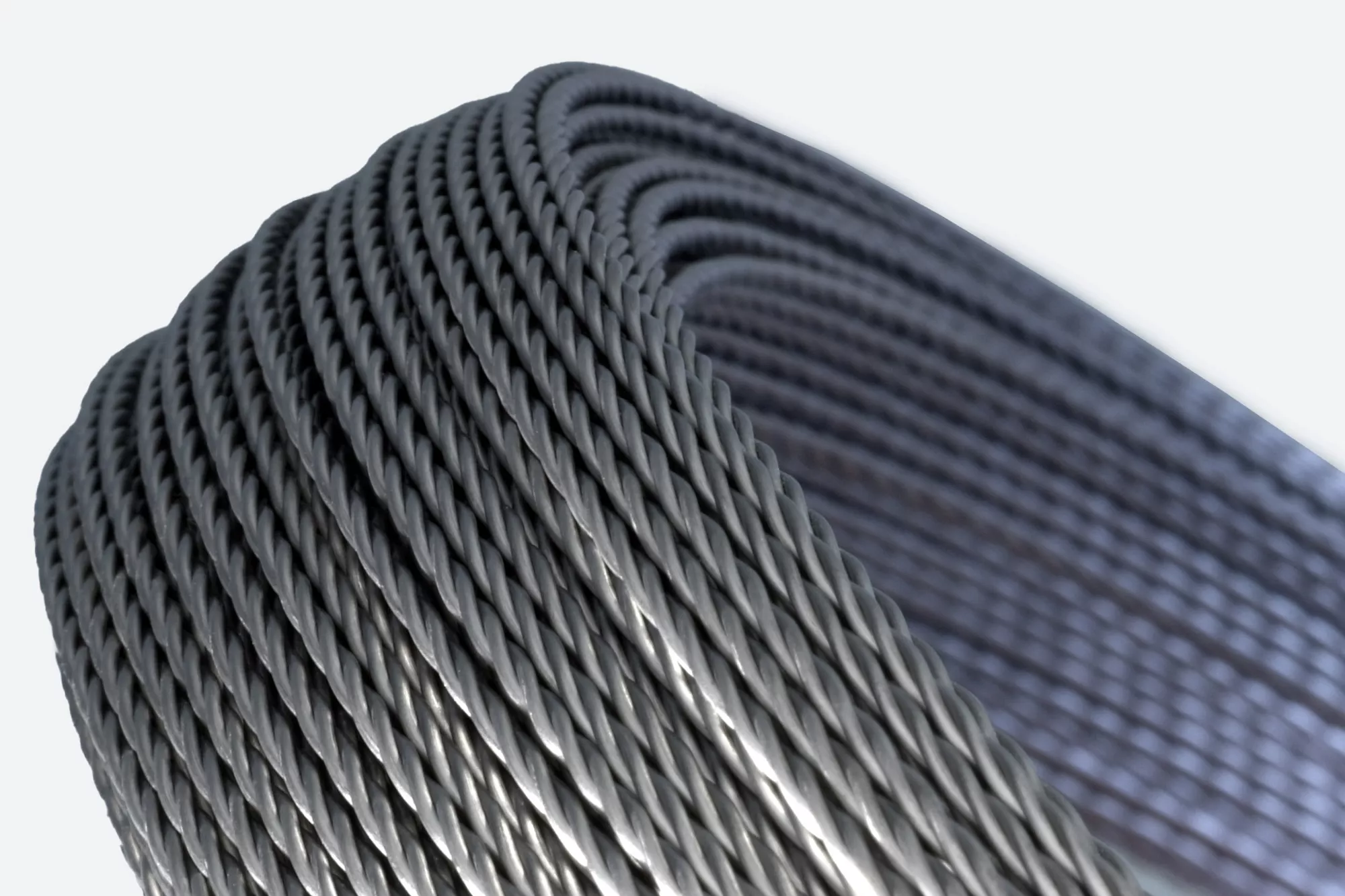

- Twisted wire

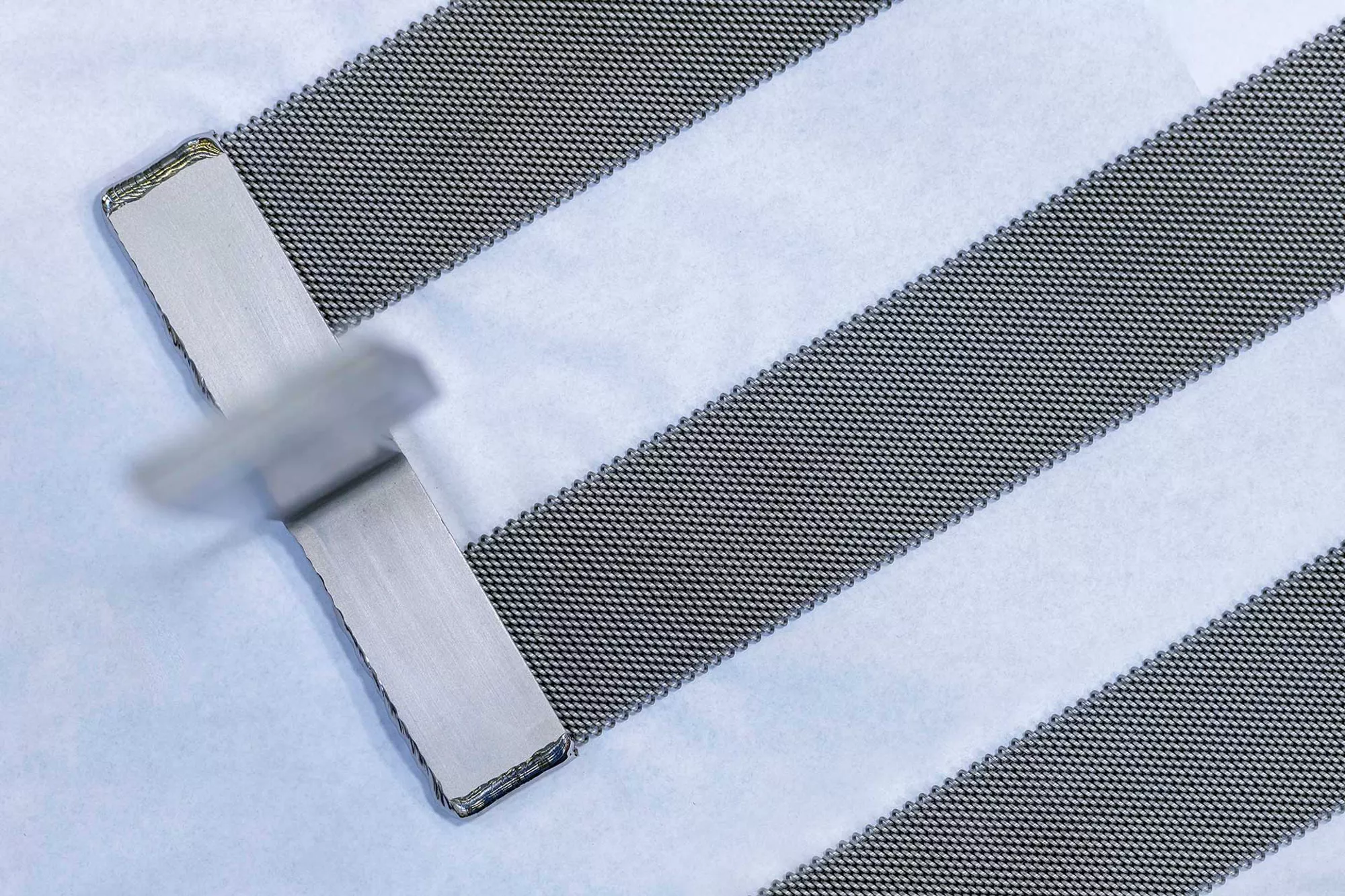

- Bundled wire

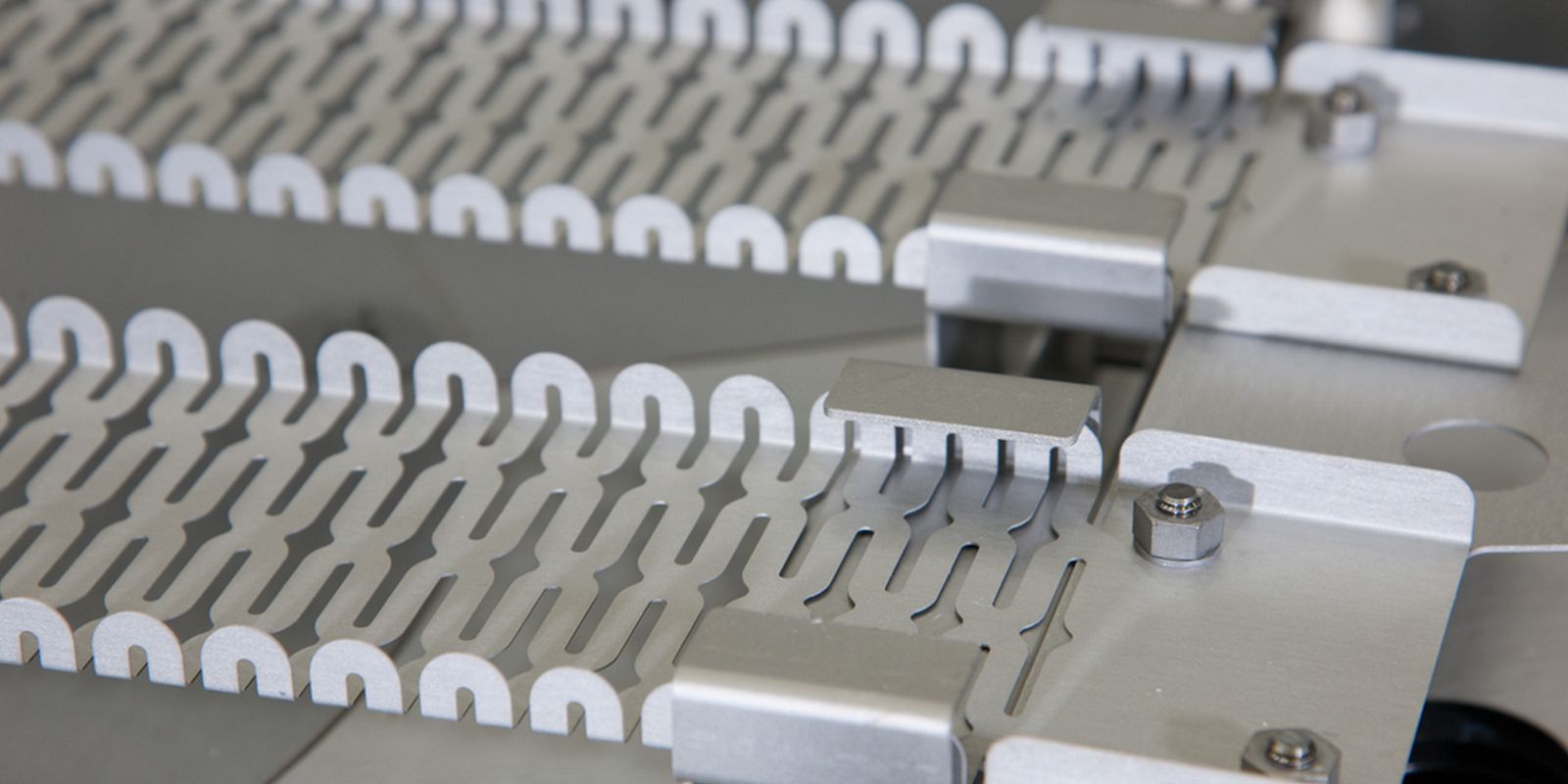

- Wire mesh heaters

Electrical current flows through the heating conductor, where it generates heat. This resistance heating creates the high temperatures in the furnace. Our components made of molybdenum, tungsten, tantalum, niobium, and their alloys are made for this. We can provide heating conductors for all types of high-temperature furnaces according to your application.

By combining different constructions and materials for our heating elements, we are able to achieve low surface loading with an even temperature distribution. This ensures that the heating elements can reliably withstand high temperatures, even over long operating periods.

High radiation output

High temperature

resistance

Low heat capacity

Low thermal

expansion

Low vapor pressure

Excellent

corrosion resistance

Our heating conductors are available as:

Bundled wire

Wire mesh heaters

Sheets

Twisted wire

Rods

Our materials belong to the refractory metals. Molybdenum and tungsten are primarily used in thermal processes under high temperatures. With their high melting point, they do not become soft, even at extremely high temperatures. Refractory metals have a low thermal coefficient of expansion and a higher thermal conductivity than steel.

Our materials are also suitable for use with protective gases such as argon, helium, nitrogen, and hydrogen.

Using suitable alloys and optimized production processes, we can improve the properties of molybdenum. To achieve a particularly high level of ductility and creep resistance, we dope pure molybdenum with small quantities of La2O3. The stabilized microstructure and modified recrystallization behavior prevent the premature embrittlement and fracture of our furnace components.

Advantages of ML compared to pure molybdenum:

Find out more about the special properties of our materials here:

Regardless of whether you need an entire hot zone or a spare part for your existing furnace, naturally we would be happy to install our products for you on-site. Our experts can also handle the inspection, maintenance, and optimization of your existing furnaces.

Should repairs become necessary, that is a task that we would be happy to take care of for you on-site. If desired, our experts can also provide a remote service to support your needs. This can often quickly answer questions and resolve problems, significantly reducing downtimes.

Whether for annealing furnaces and soldering processes, coating systems, 3D printing sintering equipment, MIM furnaces, sintering furnaces, HIP processes or single crystal growing – our products made of molybdenum, tungsten, tantalum, and niobium can withstand the highest temperatures:

Is your product not yet included? Get in touch and we'll be happy to develop a tailor-made solution for your specific application.