We have designed shieldings made of an optimized quantity of W, ML, and Mo sheet layers to keep the heat loss of your furnace as low as possible during the process. A crucial factor here is the thermal radiation exchange between the sheet layers as well as the extremely low emissivity of molybdenum. Furthermore, our shieldings made of molybdenum, tungsten, and their alloys have a low specific heat capacity, enabling fast heating and cooling rates at short evacuation times, high process purity (graphite-free shielding), and short process cycle times. This makes them extremely well suited for use in the high-vacuum and ultra-high vacuum range. Using new, tailor-made designs, we can optimize the shieldings for your application in terms of weight and energy costs.

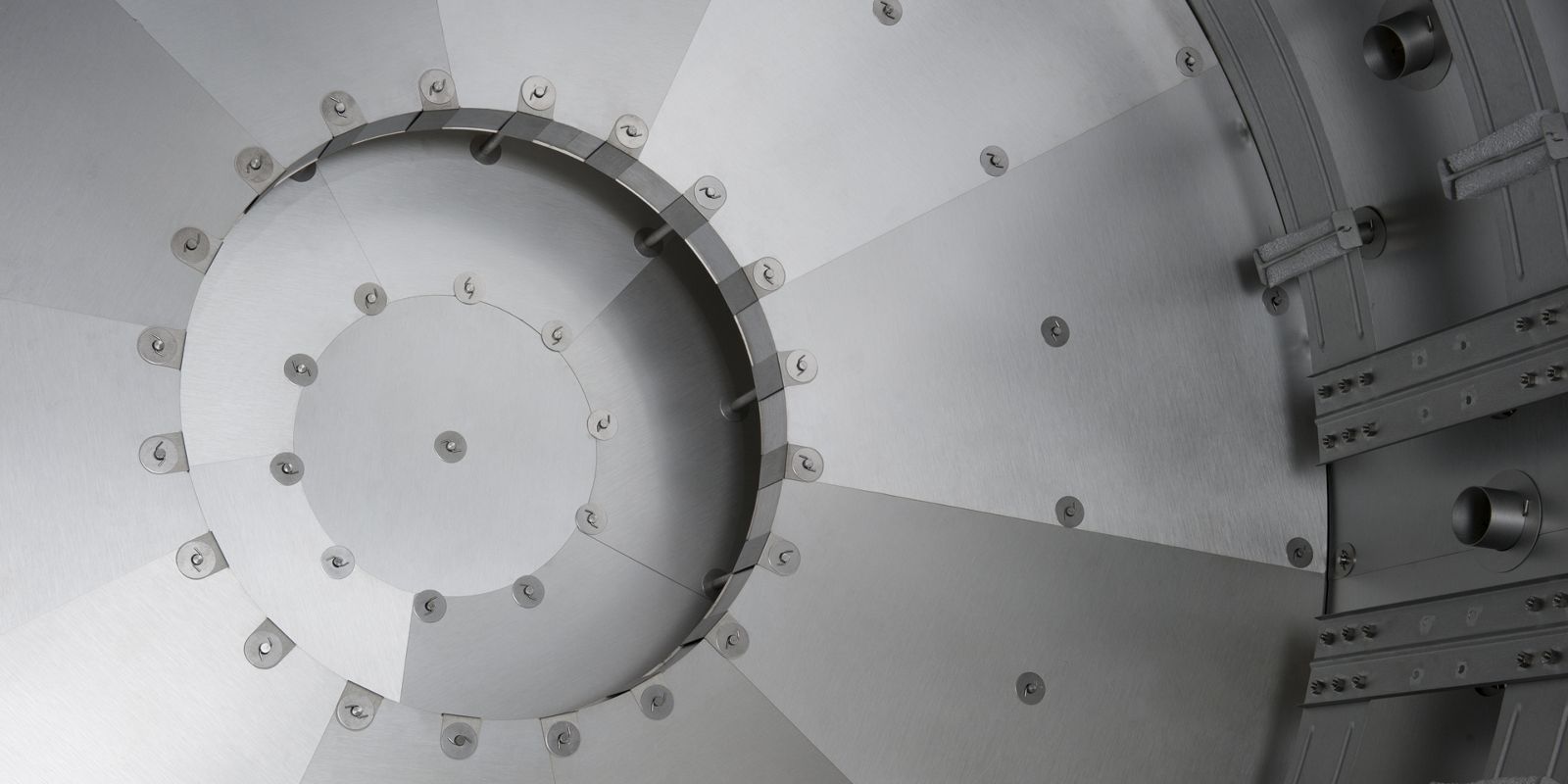

Shieldings for high-temperature furnaces

High-temperature furnaces can reach temperatures of up to 2800°C. We have developed shield packs made of refractory metals to help cool things down.

Our side shieldings, top shieldings, and bottom shieldings made of molybdenum, tungsten, ML, and stainless steel are heat-resistant with exceptional dimensional stability. We can adapt the shielding concept specifically for use in your furnace. Depending on your requirements, we can manufacture riveted, overlapping, and joint shields in any size you need.

Your advantages at a glance:

Can withstand

high temperatures up to 2800°CHigh process purity, no graphite contamination

Standard

versions as well as

customer-specific solutionsEnergy cost

optimized designShort process cycle

times possibleFor high vacuum and ultra-high vacuum

Whether remotely or on-site – we are here for you

Regardless of whether you need an entire hot zone or a spare part for your existing furnace, naturally we would be happy to install our products for you on-site. Our experts can also handle the inspection, maintenance, and optimization of your existing furnaces.

Should repairs become necessary, that is also a task that we would be happy to take care of for you on-site. If desired, our experts can also provide a remote service to support your needs. The major advantage of this is that questions and problems can be answered and solved quickly, significantly minimizing your downtimes.

Other products for high-temperature processes

Whether for annealing furnaces and soldering processes, coating systems, 3D printing sintering equipment, MIM furnaces, sintering furnaces, HIP processes, or for single crystal growing, our products made of molybdenum, tungsten, tantalum, and niobium can withstand the highest temperatures:

Can't find your product? Simply contact us and we would be happy to find a custom solution for your specific application.

You can find additional products for furnace construction as well as semifinished products in our Plansee online shop. There you can quickly and easily order configurable dimensions from stock.