Charge systems for high-temperature furnaces

Our charge carriers made of refractory metals retain their shape even at high temperatures. They are stronger than graphite products and, unlike graphite, they are extremely pure and therefore well suited for high-vacuum processes. We will select suitable materials such as ML or TZM adapted to your individual mechanical requirements and then provide you with tailored, product-specific designs.

Your advantages at a glance:

Optimized design

Tailored solutions

Dimensionally stable

High creep resistance

Our team will develop the optimal design for your application using simulations and calculation methodologies and then select the suitable material.

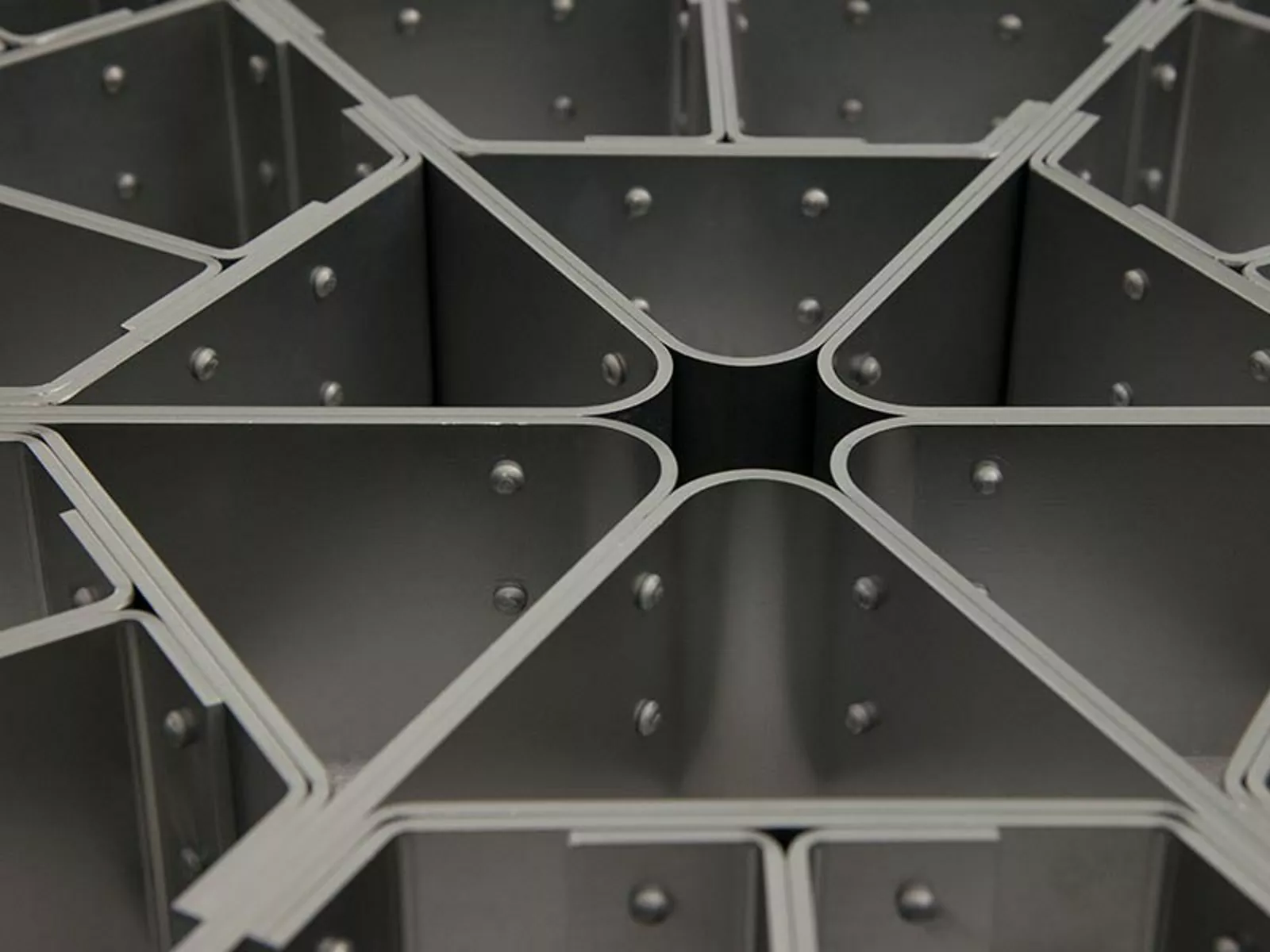

We can manufacture tailor-made charge systems for your furnace using the following elements:

- Rails, pins, and caps

- Insertable, screw-fastened, or riveted racks

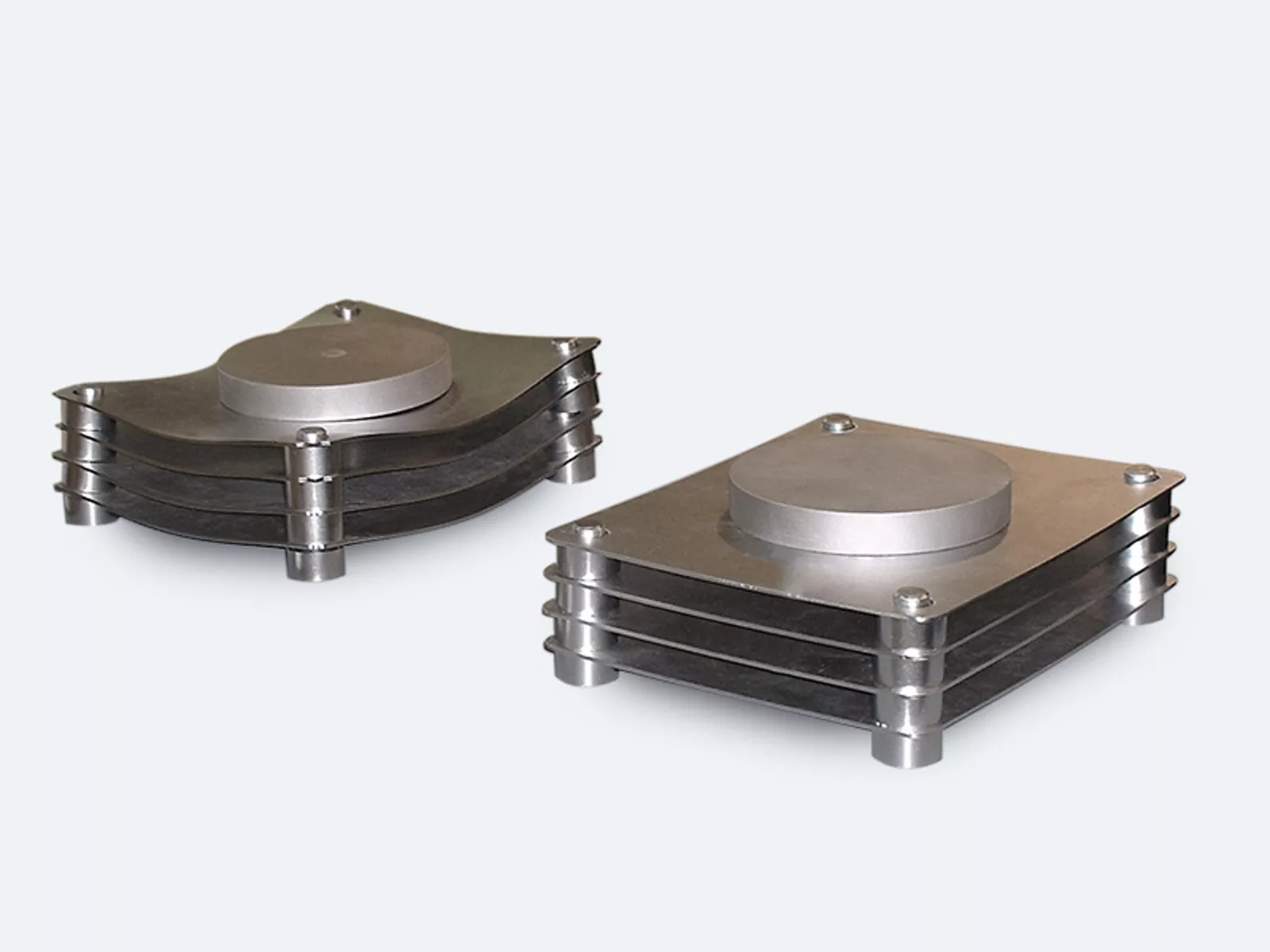

- Stackable charge carriers with fixed or variable spacings

- Base plates and boats for continuous furnaces

- Intermediate plates and frames

We would also be happy to supply our charge carrier plates with ceramic coatings. This ensures that absolutely nothing adheres to and remains stuck on the surface. We design our charge systems so that they have a high level of dimensional stability combined with the lowest possible weight.

ML and TZM for high dimensional stability

Along with molybdenum and tungsten, we manufacture our charge systems primarily out of ML and TZM. These alloys are ten times more creep-resistant than pure molybdenum. In addition, ML also remains ductile after use at high temperatures. This makes our charge systems extremely well suited for the frequent changes between high and low temperatures.

The benefits for you: low stresses and low sags ensure that our products have a particularly long service life.

The comparison clearly shows that TZM and MLR (R = recrystallized) also have a significantly higher creep resistance even at high temperatures.

Using suitable alloys and optimized production processes, we can improve the properties of molybdenum. To achieve a particularly high level of ductility and creep resistance, we dope pure molybdenum with small quantities of La2O3. The stabilized microstructure and modified recrystallization behavior prevent the premature embrittlement and fracture of our furnace components.

Advantages of ML compared to pure molybdenum:

- Higher recrystallization temperature

- Elongated grain structure for higher ductility

- Greater creep resistance

Wherever materials need to be especially robust, we strengthen the microstructure of pure molybdenum with titanium and zirconium. A Mo-Ti solid solution and Ti-Zr carbides ensure optimal strengths at temperatures up to 1400°C.

Advantages of TZM compared to pure molybdenum:

- Better creep resistance

- Higher recrystallization temperature

- Greater high-temperature stability

Whether remotely or on-site – we are here for you

Regardless of whether you need an entire hot zone or a spare part for your existing furnace, naturally we would be happy to install our products for you on-site. Our experts can also handle the inspection, maintenance, and optimization of your existing furnaces.

Should repairs become necessary, that is a task that we would be happy to take care of for you on-site. If desired, our experts can also provide a remote service to support your needs. This can often quickly answer questions and resolve problems, significantly reducing downtimes.

Further products for high-temperature processes

Whether for annealing furnaces and soldering processes, coating systems, 3D printing sintering equipment, MIM furnaces, sintering furnaces, HIP processes or single crystal growing – our products made of molybdenum, tungsten, tantalum, and niobium can withstand the highest temperatures:

Is your product not yet included? Get in touch and we'll be happy to develop a tailor-made solution for your specific application.