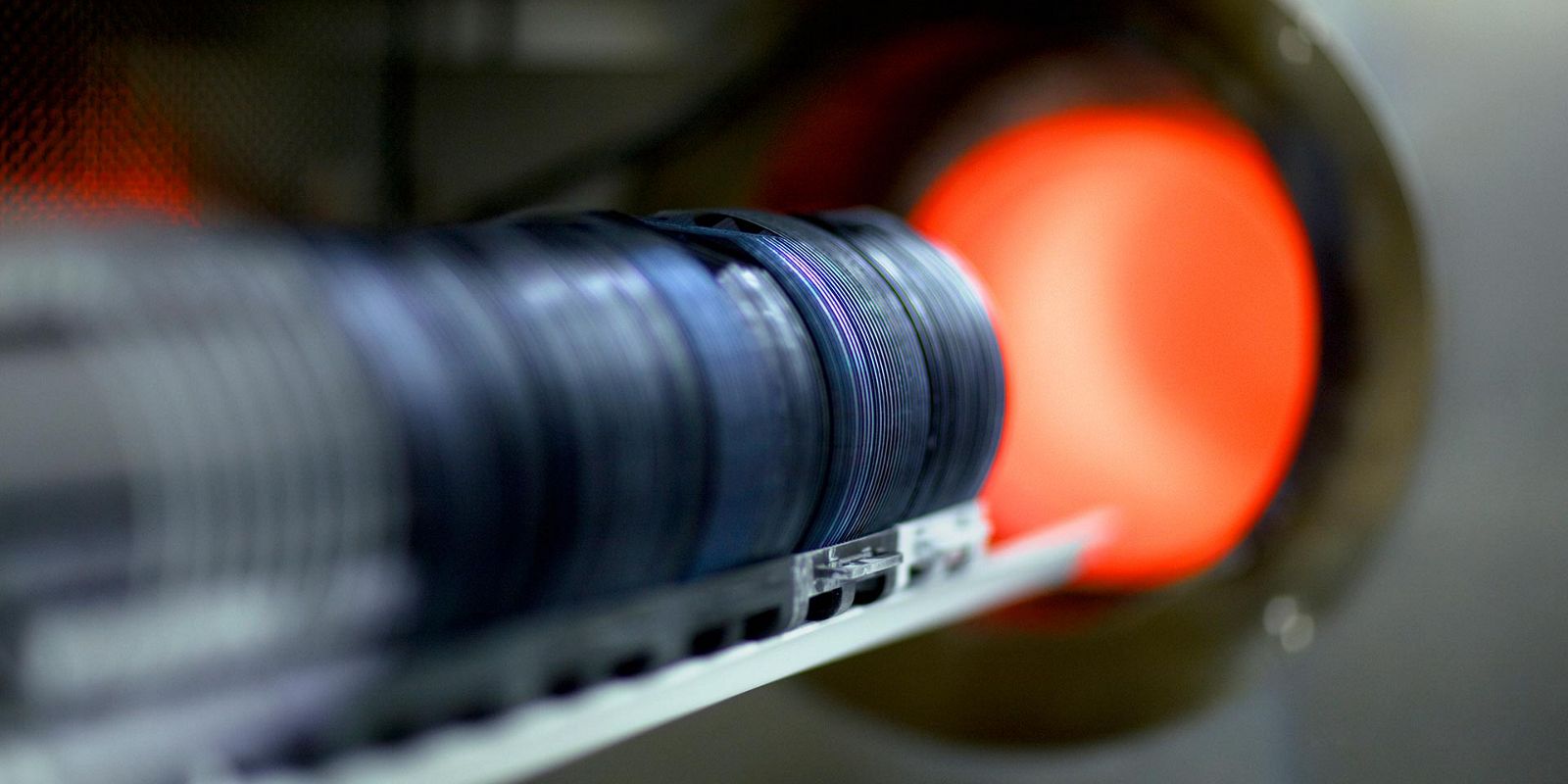

Extremely heat-resistant: components for furnace construction

Our components made from molybdenum and tungsten are used in the high-temperature furnaces of the glass and steel processing industries for hardening, annealing, and sintering. There they ensure high energy efficiency and the durability of your high-temperature furnace. Each component must meet the highest standards for this kind of hot zone. That's why we have more than ten engineers at Plansee who specialize in furnace construction and thermal processes. These development teams will stand by your side from the first drawing to the installation of the finished product on-site. We optimize our components to your requirements and tailor them to the temperature, atmosphere, and cycle time of the processes.

Thanks to our decades of experience in thermal processes, we can not only handle difficult-to-process materials, but also maintain the strictest tolerances. This guarantees precision. You will also profit from the decades of technical knowledge of our materials scientists and engineers. The same is true for our investment in mines in the West and our in-house production. A secure raw material supply and delivery capability as well as consistently high quality are thus guaranteed.

Your advantages at a glance:

Close collaboration with our development teams

Tailored

hot zonesStandard

hot zonesSound application

knowledgeInstallation on-site

Latest facilities for forming, processing, and coating

Learn more about our products for the furnace construction industry: