OLED: Reflection protection and electrode in one

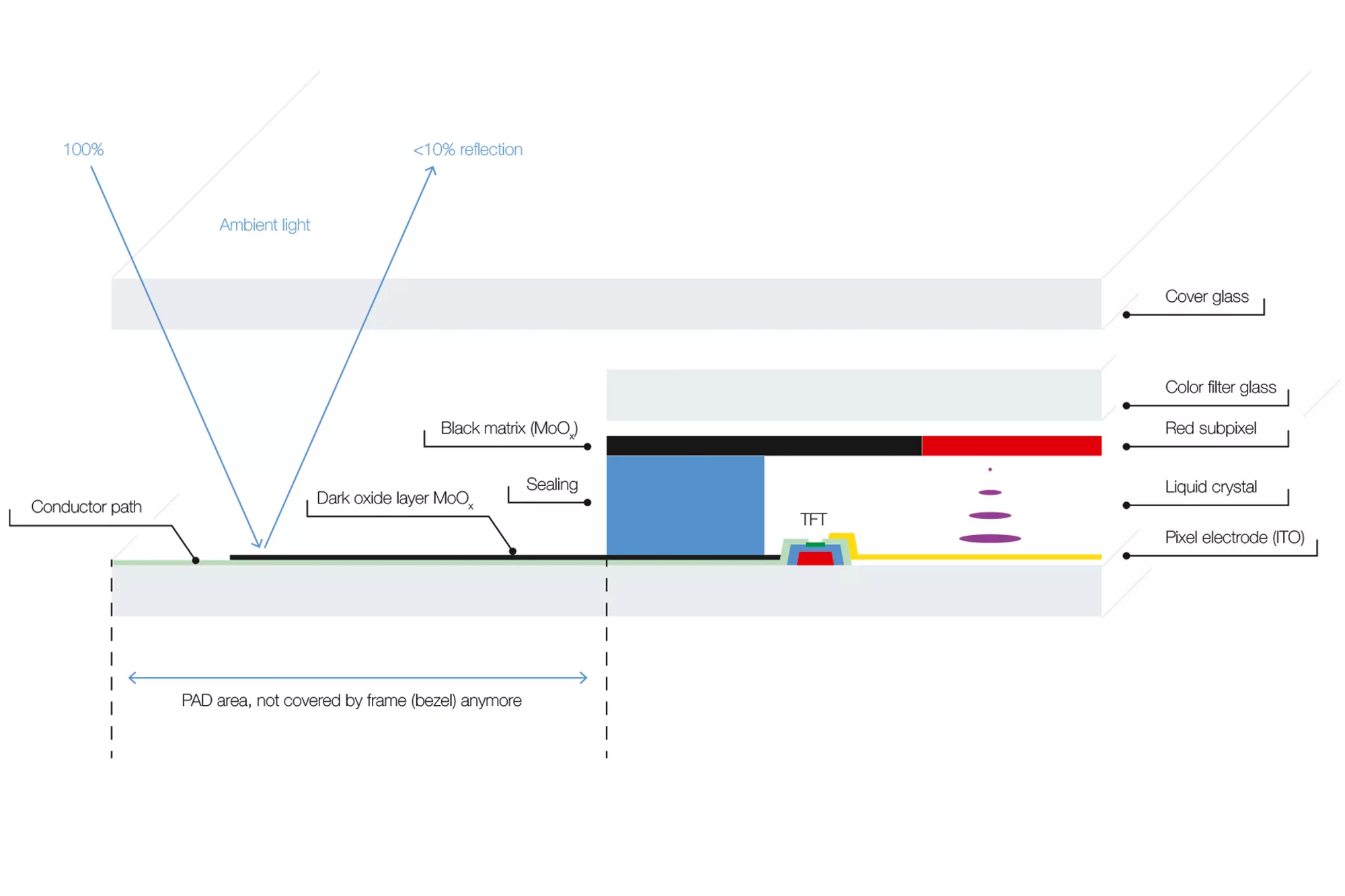

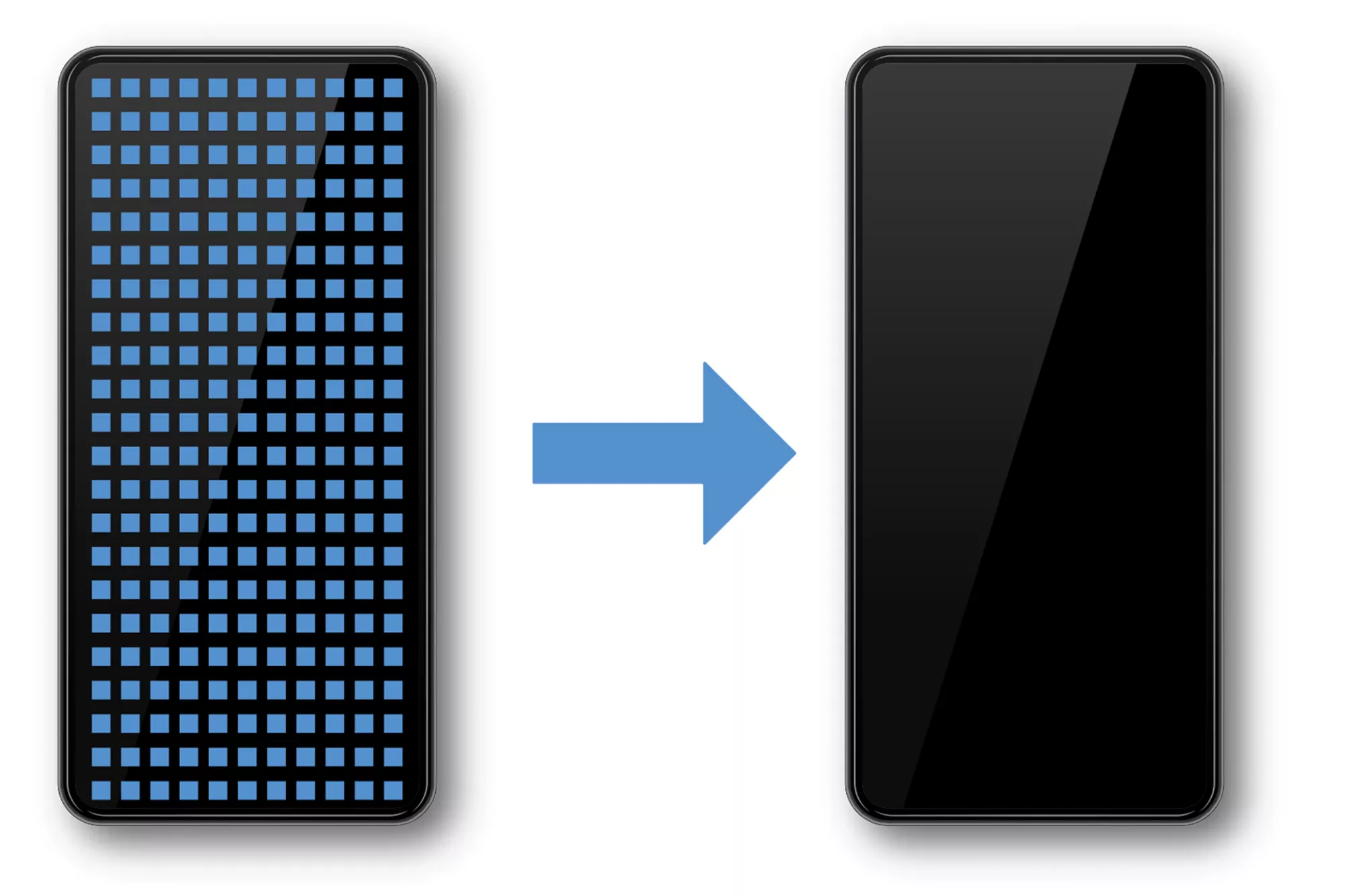

When ambient light hits OLED displays, the molybdenum layers of the TFT metallization (gate, source/drain electrodes) reflect the ambient light, thereby reducing the contrast of the display. Circular polarization filters are used to prevent these unwanted reflections. They do reduce the reflection of the electrode but also reduce the light yield of the display. As MoOx absorbs light extremely well and is also electrically conductive, this material is particularly suitable as an anti-reflective layer for the TFT metallization. Using MoOx allows OLED manufacturers to dispense with the polarization layer.

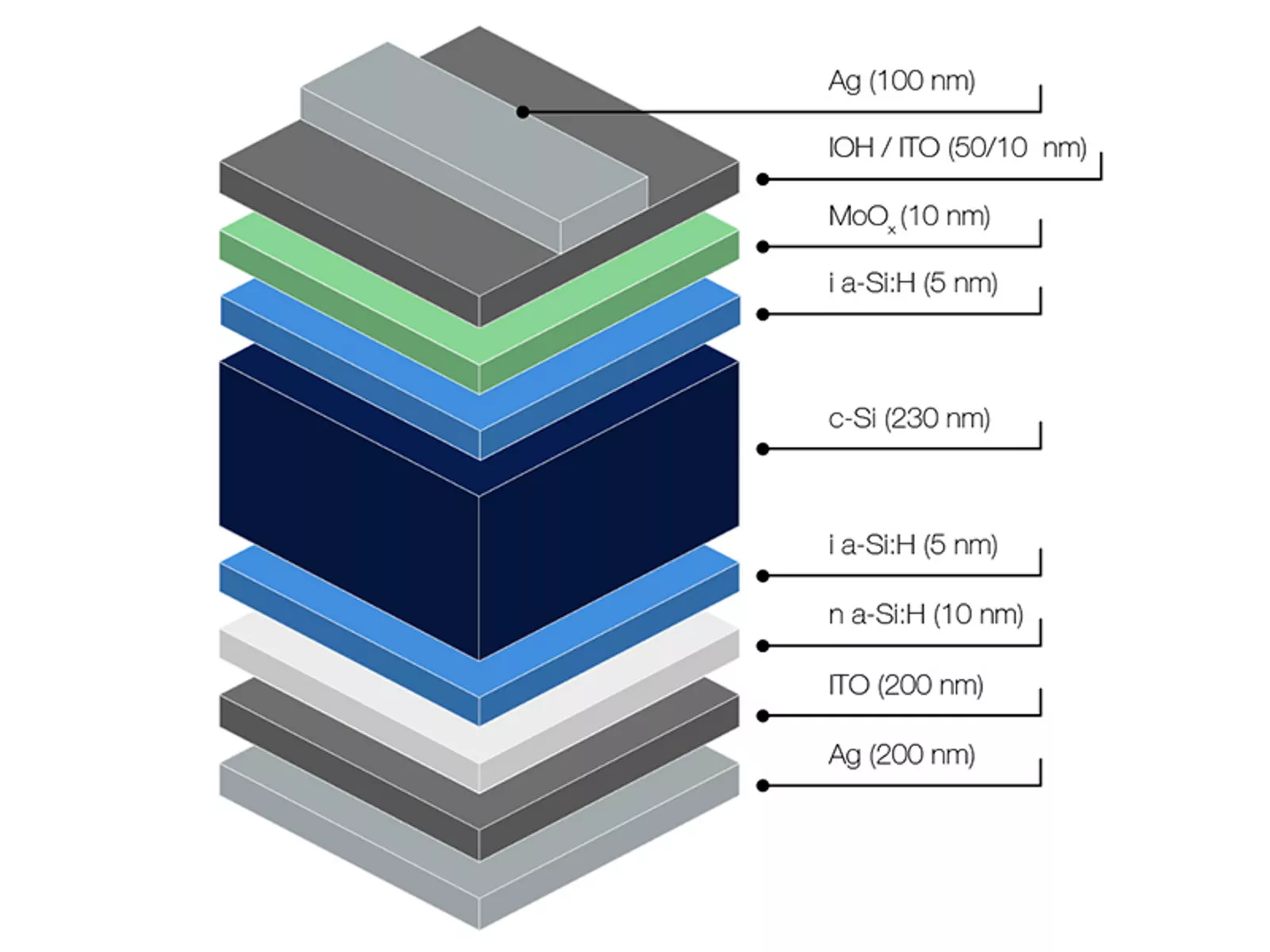

Transparent molybdenum oxide layers for OLED and solar cell technology

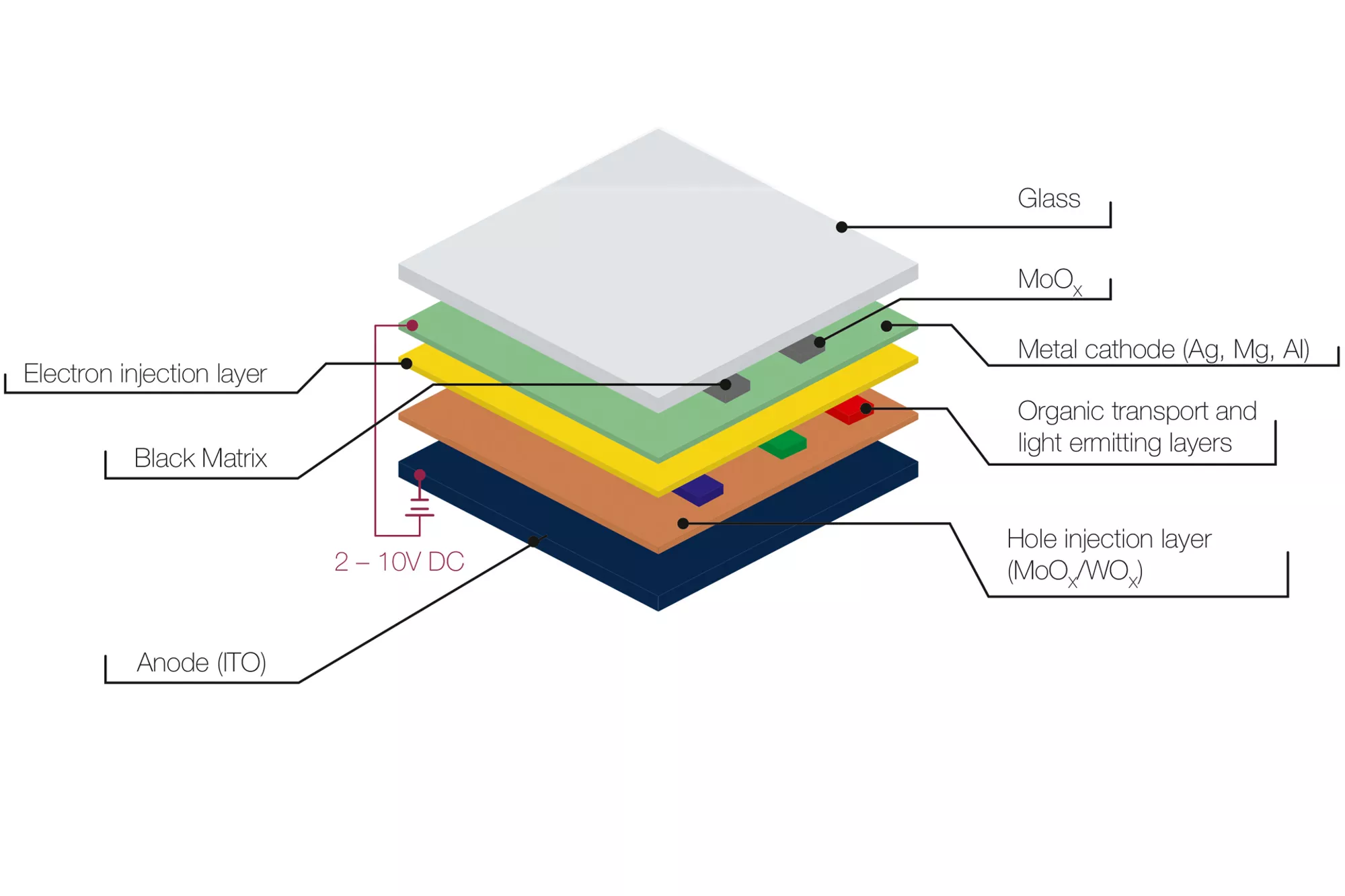

Transparent MoOx layers represent another area of application. By adding oxygen during the coating process, the oxygen content of the layers can be adjusted up to a stoichiometry of MoO3. These layers have special electronic properties, in particular a high electron work function. Transparent MoOx layers can therefore be used in OLED technology as so-called "hole injection layers" (HIL). In thin-film solar cells based on CIGS and CdTe, MoOx layers are described and used as a component in the back contact and as a barrier layer (e.g., against selenization). Organic solar cells also benefit from additional layers of MoO3.

Further details can be found in the article "Thin-film metal oxides in organic semiconductor devices: their electronic structures, work functions and interfaces" by Nature Research.