Whether tubular, round, or angular, we can provide a tailor-made target for your application. The most important information at a glance:

Aluminum-chromium sputtering targets and cathodes

Our aluminum-chromium (AlCr) targets and cathodes provide harder and more oxidation-resistant nitride coatings on drills, cutters, indexable cutting inserts, and other tools. The high hot hardness and resistance to oxidation of aluminum-chromium coatings make it possible to achieve faster feed speeds, improved cutting performance, and a higher chip volume. Just one thousandth of a millimeter of our materials reliably protects your tool against wear, even at high temperatures, and thereby extends the service life.

The advantages of our targets at a glance:

High ductility

Excellent thermal conductivity

Optimum, homogeneous microstructure

Highest material purity

Production according to your specific requirements

| Aluminum / Chromium share [At.-%] | 70 / 30 | 50 / 50 |

| Purity [%] | 99.7 | 99.7 |

| Guaranteed density [g/cm3] | 3.68 | 4.50 |

| Standard grain size / Fine grain [µm] | 100 / 50 | 100 / 50 |

Quality you can rely on

High ductility guarantees a long service life

Our sputtering targets and arc cathodes have to withstand a huge amount of stress during the coating process. Forces of up to one metric ton are applied to the material at the edge of the target. Whereas brittle materials would break, our material is particularly ductile thanks to the aluminum. To guarantee the high ductility of the AlCr targets, we mix our chromium-aluminum powder particularly carefully and then compress it by means of forming. This makes the microstructure of our materials considerably more homogeneous and finer than materials produced by means of a metal fusion process. The advantages of targets produced using powder metallurgy are that they are particularly break-proof and durable.

Excellent thermal conductivity guarantees smooth layers

Our targets and cathodes are exposed to high temperatures during the coating process. But our materials can easily withstand the extreme conditions. Thanks to their aluminum content and high material density, our cathodes and targets conduct heat particularly well and transfer the heat easily to the copper plate behind. This prevents build-ups of heat, which result in the uneven exposure of the target material as well as droplets on the surface, and enables you to achieve smoother coatings.

Optimum microstructure for the perfect layer

Coarse or fine metal powder? Forging, HIP, or other types of axial forming? We vary and combine our manufacturing processes to ensure you achieve a particularly smooth and fine layer. We never take our eyes off the goal: the optimum microstructure of our targets and cathodes. This means that considerably fewer droplets form on your product during coating. The result is particularly smooth layers.

Oerlikon Balzers is a company that relies on targets and cathodes from Plansee. The leading manufacturer of tool and component coatings is particularly impressed by the above-average performance and wide scope of applications of the aluminum-chromium-nitride coatings.

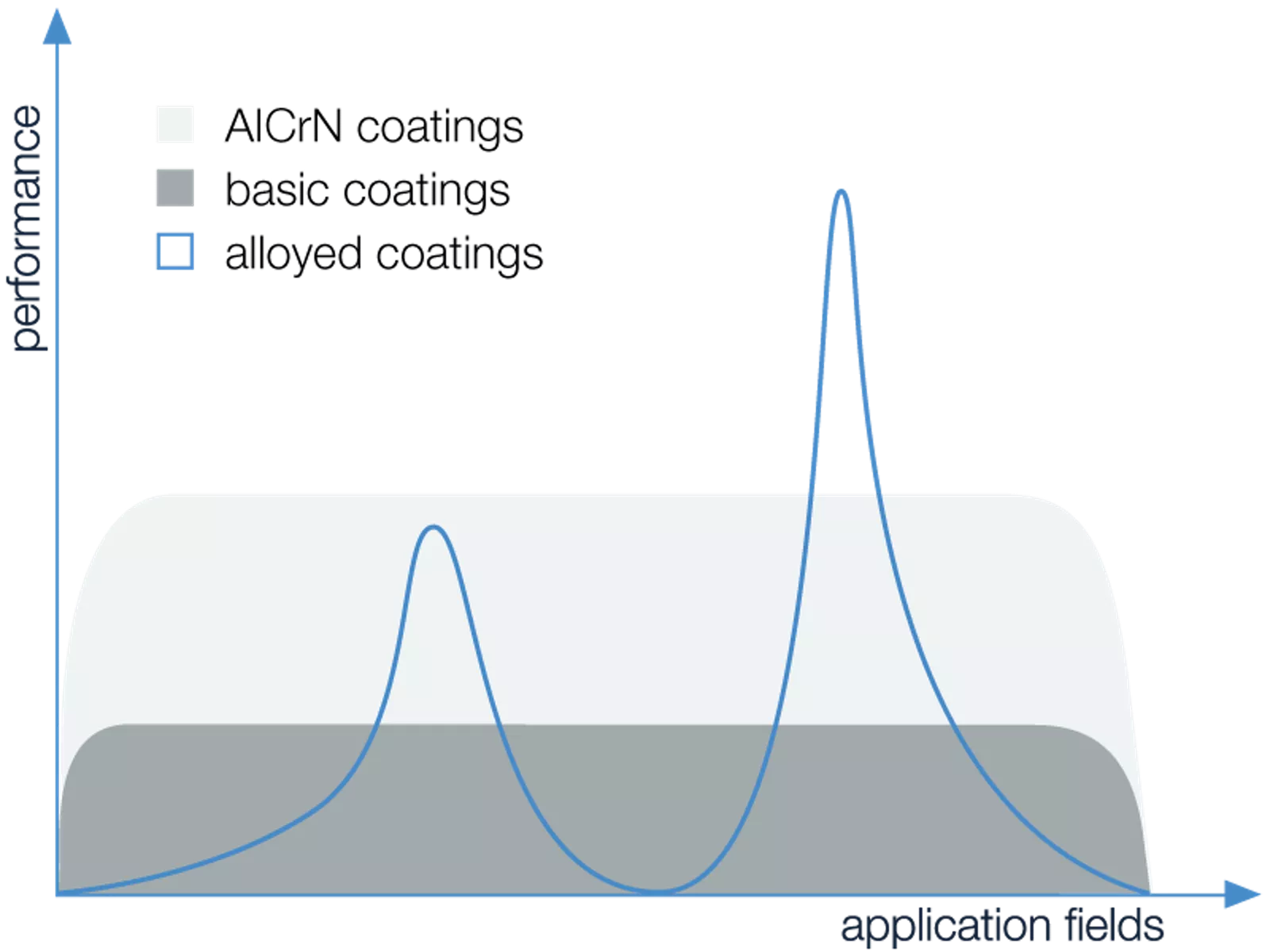

Standard coatings (referred to as 'basic coatings' in the diagram) made of TiN or TiAIN have a very wide scope of applications with good average performance. With the AlCrN coatings, our customers achieve even greater performance in just as wide a field of application. For even greater optimization in the case of special applications, the performance of the coating can be significantly improved again through the targeted use of further elements in the TiAl or AlCr targets ('alloyed coatings').

Can be used for the following coating processes

Our materials are applied by means of a reactive magnetron sputtering process or arc evaporation.

- Reactive magnetron sputtering

Hard material layers and decorative layers based on aluminum, titanium, zirconium, chromium, and ceramics are applied to tools, components, and other products by means of reactive magnetron sputtering.

The coating material is placed opposite the product to be coated as a sputtering target in a vacuum chamber. The chamber is filled with argon gas and a voltage of several hundred volts is applied. This ignites a plasma made of positively charged argon particles (argon ions) and free electrons. The positively charged argon ions are accelerated towards the negatively charged cathode (target). There they hit the target surface with a high kinetic energy of up to several hundred electron volts (eV). As a result, the argon particles force sputtering target atoms out of the surface. A potential is now applied between the vacuum chamber and the substrate. This causes the particles of the hard material to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, carbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

- Arc evaporation

During arc evaporation (arc process), hard material layers based on aluminum, titanium, zirconium, and chromium are applied to tools. In this vacuum-based coating process, the source material takes the form of an arc cathode.

A voltage of several hundred volts is applied between an anode and the positively charged arc cathode in a vacuum chamber. This creates an arc. It moves up and down on the arc cathode, melting or evaporating the smallest amounts of material. Positively charged metal ions form from around 90% of the evaporated cathode particles. A bias voltage is now applied between the vacuum chamber and the substrate. This causes the metal ions to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, hydrocarbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

Our expertise for your individual sputtering targets and arc cathodes

Are you searching for the optimum layer? Put your trust in our decades of experience and large database of chemical compositions and manufacturing processes. Our team is continuously further developing our sputtering targets and arc cathodes to improve the following material properties:

- Grain size and microstructure

- Ductility

- Material hardness

- Resistance to oxidation

- Coefficient of friction

- Temperature resistance

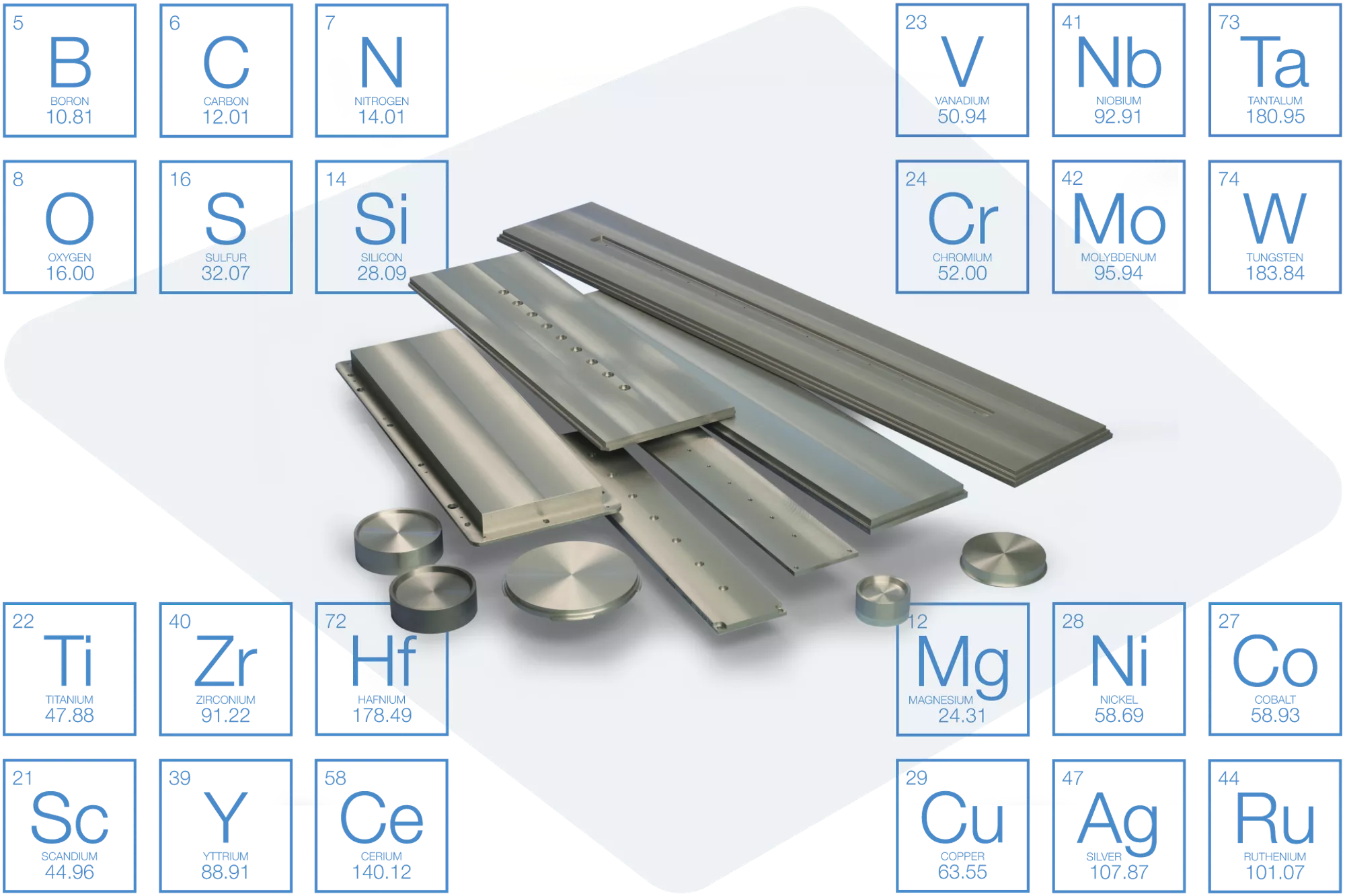

We perfect our aluminum-chromium mixture with further elements to suit your exact requirements. Get in touch!

AlCr-based coatings, for example, become more wear-resistant through the addition of small quantities of iron. This makes the coated tools more durable and resistant.

Detailed scientific insights into wear-resistant coatings made of aluminum-chromium-oxide can be found in the publication "Role of droplets and iron on the phase formation of arc evaporated Al–Cr-oxide coatings". This research paper was published by TU Wien in collaboration with the Plansee research team.

Other products for coating technology

Our aluminum-based targets and cathodes with integrated heat sinks are also available for you to test. These impress with an even higher thermal conductivity and are more stable on the edge of the target. Our aluminum heat sinks are connected directly to the target material.

Visit the product pages to find out more about our targets made of other materials: