Titanium-diboride sputtering targets

Titanium-diboride (TiB2) is known for its extreme hardness. Unlike other coatings, TiB2 does not react with aluminum. This means that no material particles can adhere to the tool tip when processing aluminum. This prevents rapid wear to tools as a result of the higher use of force involved in machining as well as the premature breaking of the tool tip. Tools coated with titanium-diboride are therefore particularly well suited to processing and machining aluminum and other nonferrous metals.

The advantages of our targets at a glance:

High density

Excellent thermal shock

resistanceOptimum, homogeneous microstructure

Highest material purity

Unsurpassed product quality

The most important properties at glance:

| Purity [%] | 99.7 |

| Guaranteed density [g/cm3] | 4.40 |

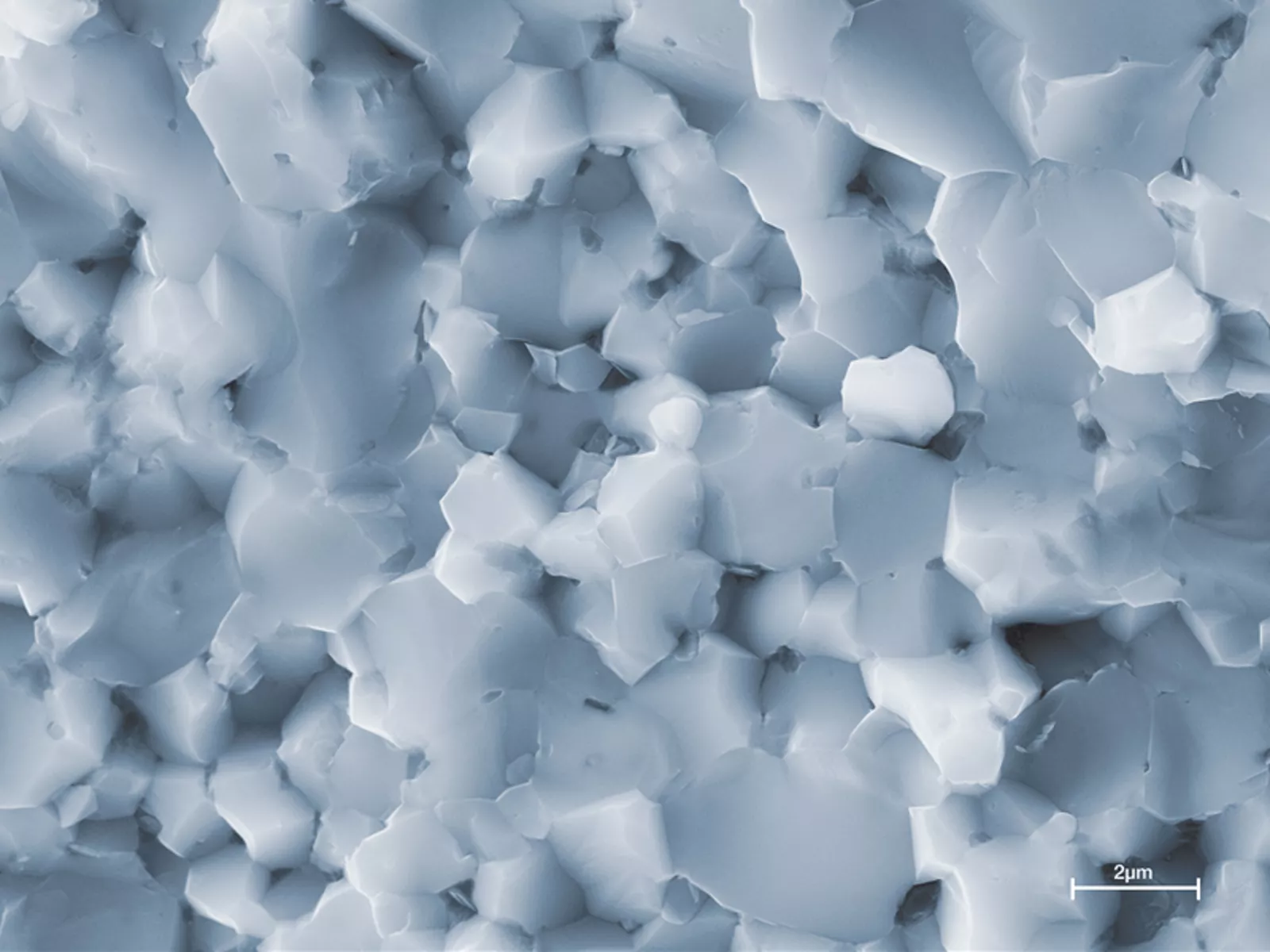

| Grain size [µm] | 2 |

| Thermal conductivity [W/(m·K)] | 64 |

| Thermal coefficient of expansion [1/K] | 7.4 · 10-6 |

Quality you can rely on

We pretreat the TiB2 powder, which means that the microstructure of our targets is extremely fine and homogeneous. The advantage of this is that the target material is stripped away evenly during the coating process and the coating is smoother.

High density guarantees smooth layers

As a ceramic material, titanium-diboride requires high temperatures of 1,700 to 2,000°C for compression. We therefore produce our targets using hot presses and thereby achieve at least 98% of the theoretical density. As a result, no powder particles are released from the target during sputtering. The result is a perfect layer structure and optimum adhesion of the coating.

Excellent thermal shock resistance guarantees a long service life

During the coating process, the target is subjected to high temperatures. Once sputtering is complete, the material cools down quickly. This can cause cracks or breaks in the target. Thanks to our special powder metallurgical manufacturing process, our targets have a particularly high thermal shock resistance and can easily withstand countless temperature cycles.

Unsurpassed material purity for top quality

The purer the coating material, the better the quality of the hard material layer. From the outset, we only use the purest powder and mix this in our own facilities to guarantee the highest material purity. We monitor every step – from the powder to the finished product – ensuring that only targets with the specific guaranteed density, purity, and a homogeneous microstructure leave our factory.

Everything from a single source – from the powder to the finished target

As a leading target manufacturer, we do everything ourselves. From mixing and pressing the metal powder to forming, machining, and bonding our targets, we also develop new materials to optimize both coating processes and layers. And of course we test the quality of our targets using state-of-the-art measurement methods.

Can be used for the following coating processes

Titanium-diboride hard material layers are applied to the tool by means of a magnetron sputtering process. We provide purely ceramic TiB2 sputtering targets for this purpose, as well as bonded targets on molybdenum or copper backing plates. Thanks to the backing plate, our bonded targets are stable, break-proof, and easy to handle. We usually use indium as the solder;

- Reactive magnetron sputteringTo the video "How PVD coating works"

Thin films of molybdenum are applied (sputtered) using the magnetron sputtering process (cathode sputtering). In this vacuum-based coating process, the source material takes the form of a sputtering target.

Plasma is ignited in a vacuum chamber by applying several hundred volts and admitting argon gas. This plasma consists of pure argon, positively charged argon particles (argon ions) and free electrons. The positively charged argon ions are accelerated towards the negatively charged cathode (target) through an electric field. There they hit the target surface with a high kinetic energy of up to several tens to a hundred electron volts (eV). Similar to a game of billiards, the argon particles force sputtering target atoms out of the surface. In this way, the coating material is slowly eroded. The atoms that are released from the target travel through the vacuum chamber toward the substrate opposite where they are deposited as a thin layer (similar to a bathroom mirror that films over with water vapor while the shower is running).

Boride targets for improved coating materials

Inside a Christian-Doppler laboratory, Plansee worked with Oerlikon Surface Solutions AG and the Institute of Materials Science and Technology at TU Wien in Vienna to research improved coating materials.

The result: W1-xTaxB2 layers. By adding up to 26 wt% tantalum to the preferred α crystal structure of WB2, the thermal stability increases from 800°C to up to 1,400°C. The research team was able to theoretically and experimentally prove that this effect is based on the stabilization of the crystal structure through gaps. The publication proves that adding tantalum does not negatively impact the very high fracture toughness of α- WB2. An important finding, as it has not previously been possible to use most diborides due to their brittleness.

Other products for coating technology

We are happy to provide the corresponding fastening materials such as graphite foils, screws, washers, and bolts, as well as arc cathodes. Visit our product pages for further materials: