We supply tubular cathodes, round cathodes, or planar sputtering targets made of chromium. These are available in the quality levels of High Purity (HP) and Ultra High Purity (UHP).

The most important information at a glance:

As a hard material layer, chromium (Cr) and chromium nitride (CrN) protect engine components such as piston rings optimally against rapid wear and thereby extend the service life of important components. For other components, such as bucket tappets, chromium is used as an adhesive layer for the DLC (Diamond Like Carbon) coating. Our chromium can also be used as a decorative layer on watches, electronic items, control elements, and many other products to give a brilliant shine.

Optimized design

Possibility of bonding

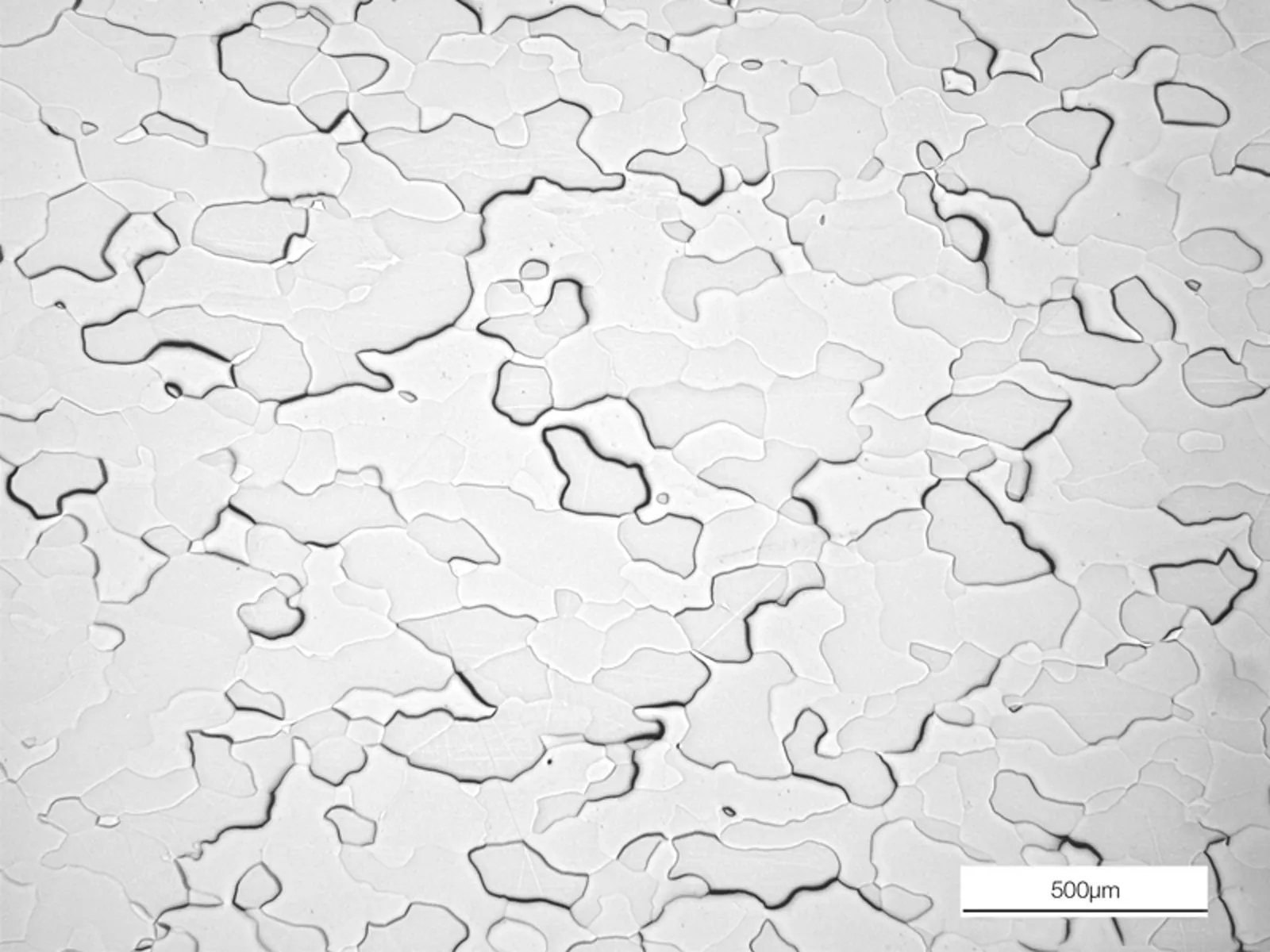

Optimum, homogeneous microstructure

Highest material purity

We supply tubular cathodes, round cathodes, or planar sputtering targets made of chromium. These are available in the quality levels of High Purity (HP) and Ultra High Purity (UHP).

The most important information at a glance:

| Chromium | UHP | HP | |

| Metallic purity [%] | 99.95 | 99.8 | |

| Metallic impurities [μg/g] | Fe Si others |

300 100 150 |

1500 500 400 |

| Non-metallic impurities [μg/g] | O N C |

300 200 100 |

1,000 200 300 |

| Guaranteed density [g/cm3] | 7.12 | 7.12 | |

| Grain size [µm] | 100 | 100 | |

| Thermal conductivity [W/(m·K)] | max. 250 | max. 150 | |

| Thermal coefficient of expansion [1/K] | 7 · 10-6 | 7 · 10-6 | |

The purer the coating material, the better the quality of the hard material layer. From the outset, we only use the purest powder and mix this in our own facilities to guarantee the highest material purity. We monitor every step – from the powder to the finished product – ensuring that only targets with the specific guaranteed density, purity, and a homogeneous microstructure leave our factory.

As a leading target manufacturer, we do everything ourselves. From mixing and pressing the metal powder to forming, machining, and bonding our targets, we also develop new materials to optimize both coating processes and layers. And of course we test the quality of our targets using state-of-the-art measurement methods.

If there's something we know for sure, it's that everything in the PVD coating process must be perfectly matched. It is only with the perfect interplay between high-quality sputtering targets, arc cathodes, and process parameters that the layer that suits your exact requirements can be produced. This means that new coating materials are continuously being developed in cooperation with our customers and numerous development institutes.

Decorative chromium coatings are applied by means of a magnetron sputtering process. Wear-resistant- and adhesive coatings can also be produced by means of arc evaporation.

Thin films of molybdenum are applied (sputtered) using the magnetron sputtering process (cathode sputtering). In this vacuum-based coating process, the source material takes the form of a sputtering target.

Plasma is ignited in a vacuum chamber by applying several hundred volts and admitting argon gas. This plasma consists of pure argon, positively charged argon particles (argon ions) and free electrons. The positively charged argon ions are accelerated towards the negatively charged cathode (target) through an electric field. There they hit the target surface with a high kinetic energy of up to several tens to a hundred electron volts (eV). Similar to a game of billiards, the argon particles force sputtering target atoms out of the surface. In this way, the coating material is slowly eroded. The atoms that are released from the target travel through the vacuum chamber toward the substrate opposite where they are deposited as a thin layer (similar to a bathroom mirror that films over with water vapor while the shower is running).

During arc evaporation (arc process), hard material layers based on aluminum, titanium, zirconium, and chromium are applied to tools. In this vacuum-based coating process, the source material takes the form of an arc cathode.

A voltage of several hundred volts is applied between an anode and the positively charged arc cathode in a vacuum chamber. This creates an arc. It moves up and down on the arc cathode, melting or evaporating the smallest amounts of material. Positively charged metal ions form from around 90% of the evaporated cathode particles. A bias voltage is now applied between the vacuum chamber and the substrate. This causes the metal ions to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, hydrocarbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

Are you searching for the optimum layer? Put your trust in our decades of experience and large database of chemical compositions and manufacturing processes. Our team is continuously further developing our sputtering targets and arc cathodes to improve the following material properties:

We perfect our chromium mixture with further elements to suit your exact requirements. Get in touch!

We'll also be happy to provide the appropriate fastening materials such as graphite foils, screws, washers, and bolts and bond your target to molybdenum or copper backing plates. These make our targets more stable and break-proof. We usually use indium as the solder; however, we can also use other materials depending on the application.