Our targets and cathodes are available from stock in the following typical material compositions in different dimensions:

- TiSi 85/15%

- TiSi 80 / 20%

- TiSi 75 / 25%

The most important information at a glance:

Titanium and silicon (TiSi) make the perfect team as a nitride hard material layer. Silicon guarantees a high resistance to oxidation, while titanium provides the special hardness. Both elements in combination are wear-resistant up to very high temperatures.

TiSiN-coated tools are extremely resistant to wear and make it possible to work at high cutting speeds. It is even possible to carry out chipping without coolant. Even tough materials such as nickel-based alloys and titanium materials can be machined easily with tools that have been coated with titanium silicon nitride.

High ductility

Excellent thermal conductivity

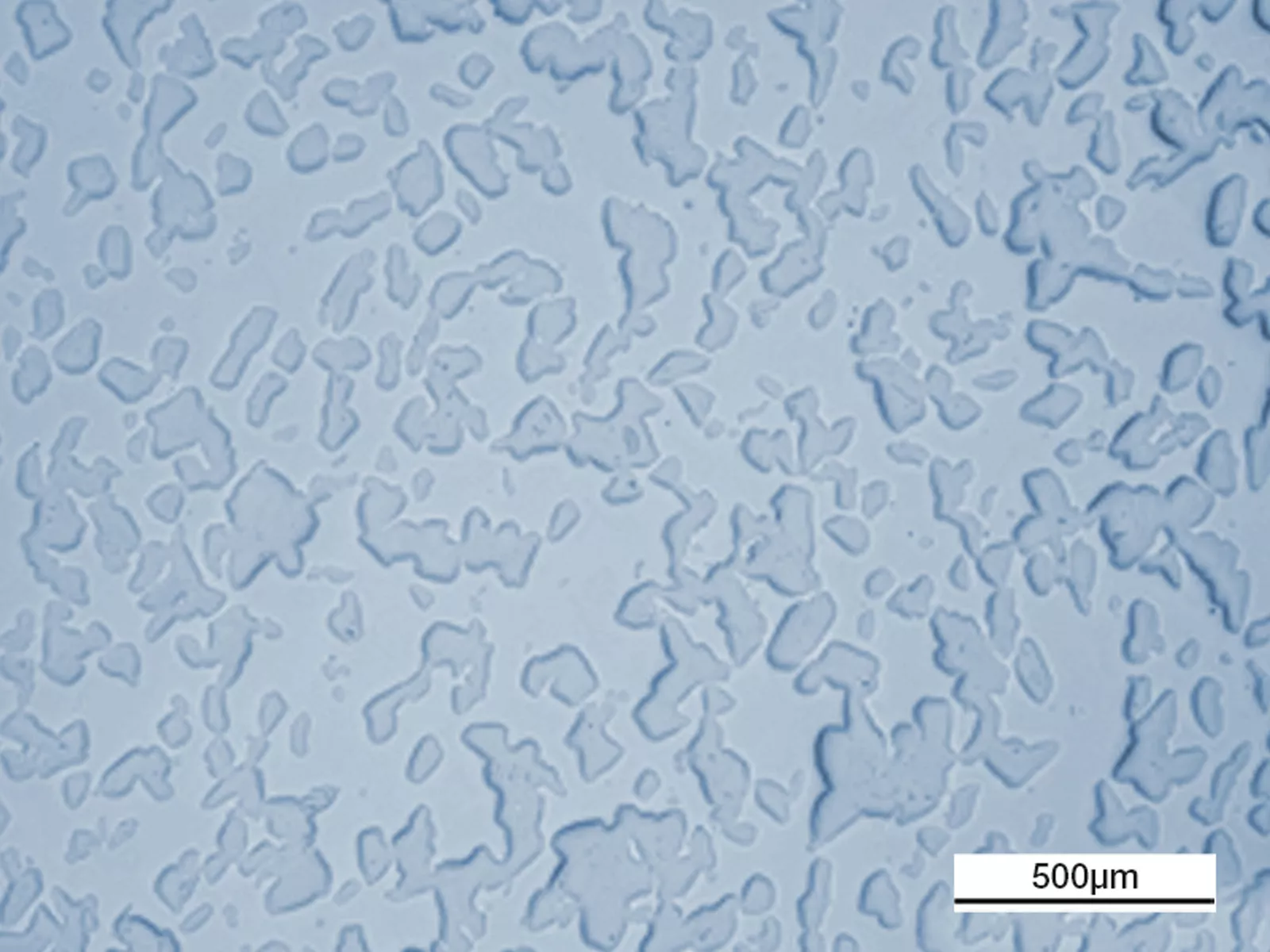

Optimum, homogeneous microstructure

Highest material purity

Our targets and cathodes are available from stock in the following typical material compositions in different dimensions:

The most important information at a glance:

| Titanium / Silicon share [% by weight] | 85 / 15 | 80 / 20 | 75 / 25 |

| Purity [%] | 99.8 | 99.8 | 99.8 |

| Guaranteed density [g/cm3] | 4.40 | 4.37 | 4.35 |

| Grain size [µm] | 100 | 100 | 100 |

The fact that we mix the powders carefully means that the microstructure of our materials is considerably more homogeneous and finer than materials produced by means of a metal fusion process. This means that considerably fewer droplets form on your product during coating. The result is particularly smooth layers.

Targets and cathodes have to withstand a huge amount of stress during the coating process. Forces of up to one metric ton are applied to the material at the edge of the target. In the case of brittle materials, the target can therefore break. As phase fractions containing silicon are embedded in a matrix of pure titanium in our material, our targets are particularly ductile. Our targets also achieve a high density thanks to our powder metallurgical manufacturing process. The result is break-proof targets.

The purer the coating material, the better the quality of the hard material layer. From the outset, we only use the purest powder and mix this in our own facilities to guarantee the highest material purity. We monitor every step – from the powder to the finished product – ensuring that only targets with the specific guaranteed density, purity, and a homogeneous microstructure leave our factory.

As a leading target manufacturer, we do everything ourselves. From mixing and pressing the metal powder to forming, machining, and bonding our targets, we also develop new materials to optimize both coating processes and layers. And of course we test the quality of our targets using state-of-the-art measurement methods.

If there's something we know for sure, it's that everything in the PVD coating process must be perfectly matched. It is only with the perfect interplay between high-quality sputtering targets, arc cathodes, and process parameters that the layer that suits your exact requirements can be produced. This means that new coating materials are continuously being developed in cooperation with our customers and numerous development institutes.

The titanium nitride crystals are embedded in an amorphous Si3N4 matrix and together form a ceramic nanocomposite coating. TiSiN layers are applied to the tool by means of a reactive magnetron sputtering process or arc evaporation.

Hard material layers and decorative layers based on aluminum, titanium, zirconium, chromium, and ceramics are applied to tools, components, and other products by means of reactive magnetron sputtering.

The coating material is placed opposite the product to be coated as a sputtering target in a vacuum chamber. The chamber is filled with argon gas and a voltage of several hundred volts is applied. This ignites a plasma made of positively charged argon particles (argon ions) and free electrons. The positively charged argon ions are accelerated towards the negatively charged cathode (target). There they hit the target surface with a high kinetic energy of up to several hundred electron volts (eV). As a result, the argon particles force sputtering target atoms out of the surface. A potential is now applied between the vacuum chamber and the substrate. This causes the particles of the hard material to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, carbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

During arc evaporation (arc process), hard material layers based on aluminum, titanium, zirconium, and chromium are applied to tools. In this vacuum-based coating process, the source material takes the form of an arc cathode.

A voltage of several hundred volts is applied between an anode and the positively charged arc cathode in a vacuum chamber. This creates an arc. It moves up and down on the arc cathode, melting or evaporating the smallest amounts of material. Positively charged metal ions form from around 90% of the evaporated cathode particles. A bias voltage is now applied between the vacuum chamber and the substrate. This causes the metal ions to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, hydrocarbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

Are you searching for the optimum layer? Put your trust in our decades of experience and large database of chemical compositions and manufacturing processes.

Our team is continuously further developing our sputtering targets and arc cathodes to improve the following material and coating properties:

We also perfect our titanium-silicon mixture with further elements to suit your exact requirements. Get in touch!

Tests in the Christian-Doppler laboratory of TU Wien in Vienna were carried out to investigate the fracture toughness of Ti-Si-N layers, which were produced with special Ti-TiSi2 targets from Plansee.

In cooperation with Oerlikon Surface Solutions AG and TU Wien, and the Institute of Material Science and Technology, Plansee determined quantitative fracture toughness values for Ti-Si-N layers by means of micromechanical tests using a scanning electron microscope. The study reveals the dependency of the fracture toughness on the phase composition and microstructure of Ti-Si-N layers, which were produced with special Ti-TiSi2 targets from Plansee.

Detailed results of the research were published by the International Journal of Refractory Metals and Hard Materials under the title "Fracture toughness of Ti-Si-N thin films".

We are happy to provide the corresponding fastening materials such as graphite foils, screws, washers, and bolts. Visit our product pages to find out more about targets made of other materials: