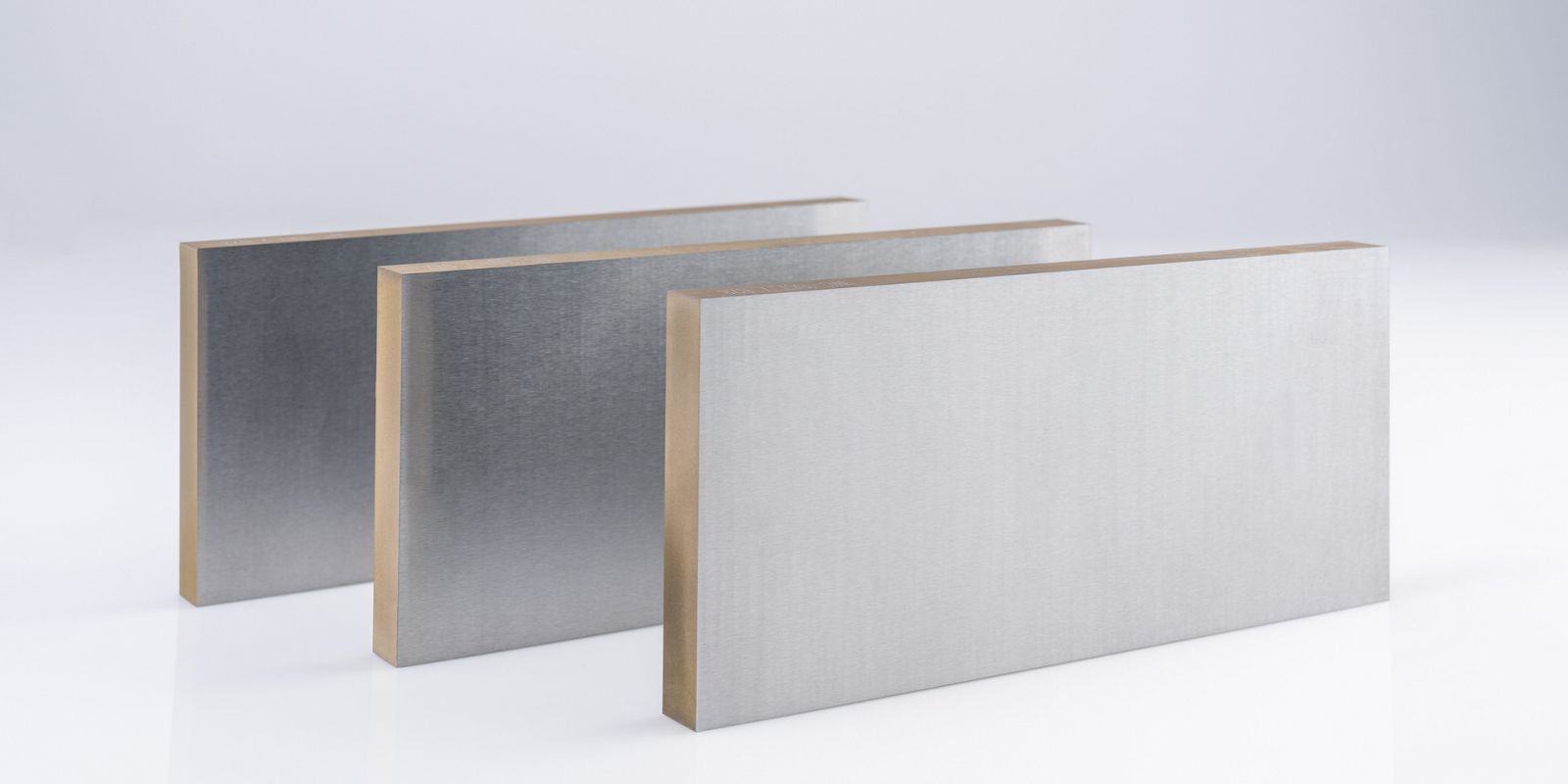

High density guarantees smooth layers

As a ceramic material, tungsten carbide requires high temperatures of 1,900 to 2,200°C for compression. We therefore produce our targets using hot presses and thereby achieve at least 99% of the theoretical density. As a result, no powder particles are released from the target during sputtering and the coating adheres perfectly.

Optimum microstructure for the perfect layer

We use tungsten carbide powder with the smallest grain size as the raw material, which means that the microstructure of our targets is extremely fine and homogeneous. The advantage of this is that the target material is stripped away evenly during the coating process and the coating is smoother. Through the further optimization of the microstructure, we can also use tungsten carbide to manufacture arc cathodes.

Excellent thermal resistance guarantees a long service life

During the coating process, the target is subjected to high temperatures. Once sputtering is complete, the material cools down quickly. This can cause cracks or breaks in the target. Thanks to our special manufacturing process, our targets have a particularly high thermal shock resistance and can easily withstand countless temperature cycles.

Maximum material purity for top quality

The purer the coating material, the better the quality of the hard material layer. From the outset, we only use the purest powder and mix this in our own facilities to guarantee the highest material purity. We monitor every step – from the powder to the finished product – ensuring that only targets with the specific guaranteed density, purity, and a homogeneous microstructure leave our factory.