We keep semifinished products such as sheets, tubes, and rods in stock to guarantee short delivery times. We provide both materials as sputtering targets and arc cathodes in all common sizes and shapes.

The most important information at a glance:

Whether it's drills, cutters, or indexable cutting inserts, we can protect your tool cost-effectively and reliably against wear with nitride and carbide layers of titanium (Ti) and zirconium (Zr). Zirconium is also suitable for decorative coatings in brass-like colors, for example on control elements and fittings.

High ductility

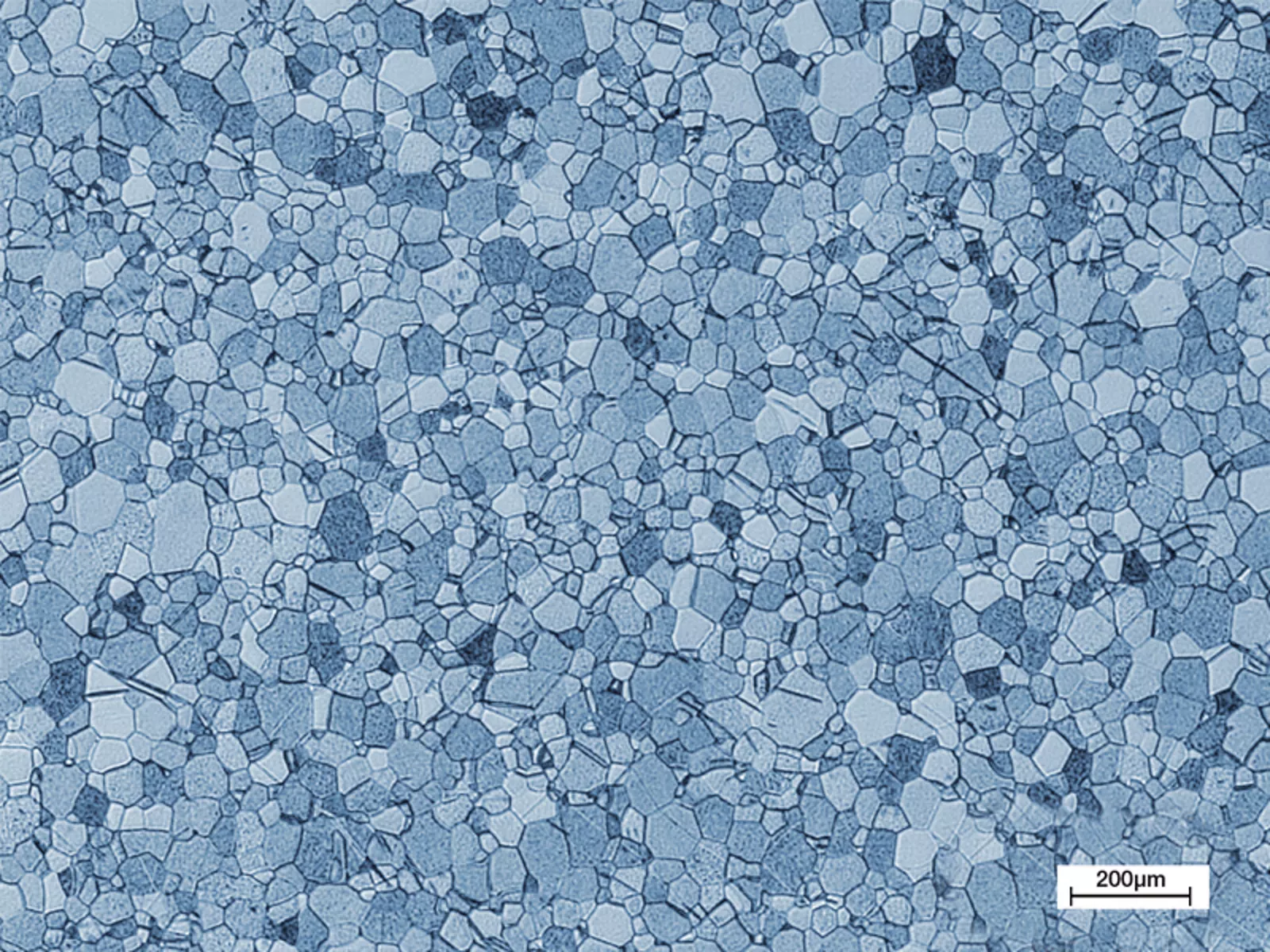

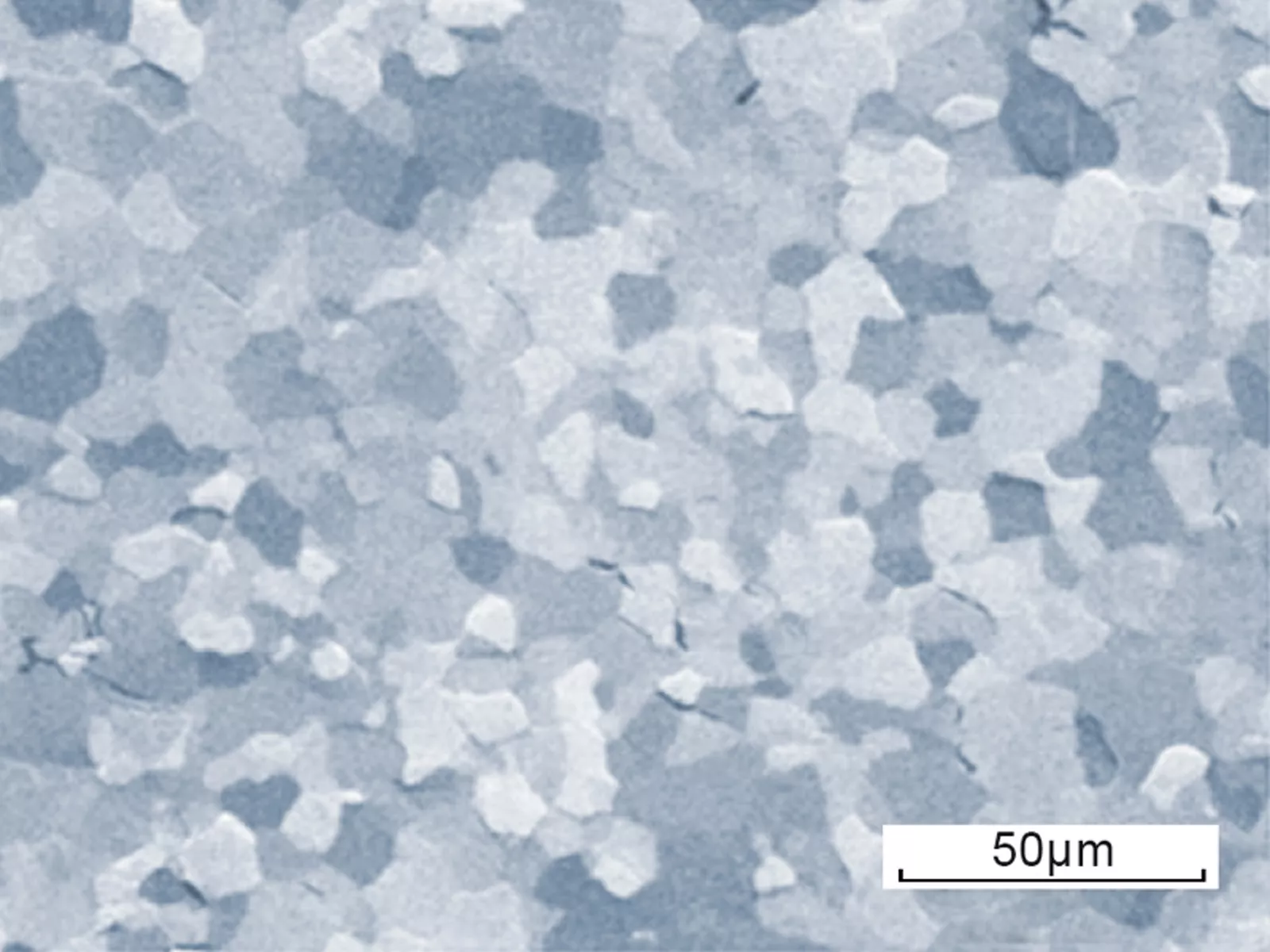

Optimum, homogeneous microstructure

Highest material purity

We keep semifinished products such as sheets, tubes, and rods in stock to guarantee short delivery times. We provide both materials as sputtering targets and arc cathodes in all common sizes and shapes.

The most important information at a glance:

| Material | Titanium | Zirconium |

| Purity [%] | 99.6 | 99.2 |

| Guaranteed density [g/cm3] | 4.5 | 6.5 |

| Grain size [µm] | 100 | 100 |

| Thermal conductivity [W/(m·K)] | 22.0 | 22.7 |

| Thermal coefficient of expansion [1/K] | 8.6 · 10-6 | 4.8 · 10-6 |

Commercially available titanium is available in four different quality grades (Grades 1, 2, 3, and 4). The quality grade that is used depends on the corrosion resistance, ductility, and strength required for the application in question. Grade 1 has the highest deformability, whereas Grade 4 has the highest strength and a moderate deformability.

The most commonly used grade of titanium for PVD coating applications is Grade 2. We keep a large and varied stock of Grade 2 titanium rolled products, such as plates, sheets, and rods, in stock to guarantee short delivery times for our customers. We machine and process these semifinished products for you using complex machining processes.

Commercially available pure zirconium naturally contains 1-5% hafnium, as it is extremely difficult to separate these two elements. Unalloyed zirconium is known as alloy 702. Zirconium targets are often used as ZrN layers for decorative applications. These have a brass-like color and a higher corrosion resistance than TiN layers. We offer our customers zirconium targets in all standard dimensions.

Coatings made of titanium and zirconium are applied by means of a reactive magnetron sputtering process or arc evaporation.

Hard material layers and decorative layers based on aluminum, titanium, zirconium, chromium, and ceramics are applied to tools, components, and other products by means of reactive magnetron sputtering.

The coating material is placed opposite the product to be coated as a sputtering target in a vacuum chamber. The chamber is filled with argon gas and a voltage of several hundred volts is applied. This ignites a plasma made of positively charged argon particles (argon ions) and free electrons. The positively charged argon ions are accelerated towards the negatively charged cathode (target). There they hit the target surface with a high kinetic energy of up to several hundred electron volts (eV). As a result, the argon particles force sputtering target atoms out of the surface. A potential is now applied between the vacuum chamber and the substrate. This causes the particles of the hard material to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, carbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

Zirconium and chromium applied to tools. In this vacuum-based coating process, the source material takes the form of an arc cathode.

A voltage of several hundred volts is applied between an anode and the positively charged arc cathode in a vacuum chamber. This creates an arc. It moves up and down on the arc cathode, melting or evaporating the smallest amounts of material. Positively charged metal ions form from around 90% of the evaporated cathode particles. A bias voltage is now applied between the vacuum chamber and the substrate. This causes the metal ions to accelerate towards the workpiece to be coated. There they react with a reactive gas that has been introduced (nitrogen, hydrocarbon, or oxygen) and are deposited as a thin nitride, carbide, or oxide hard material layer on the workpiece.

We also provide the corresponding fastening materials such as graphite foils, screws, washers, and bolts.

Visit our product pages for further materials: