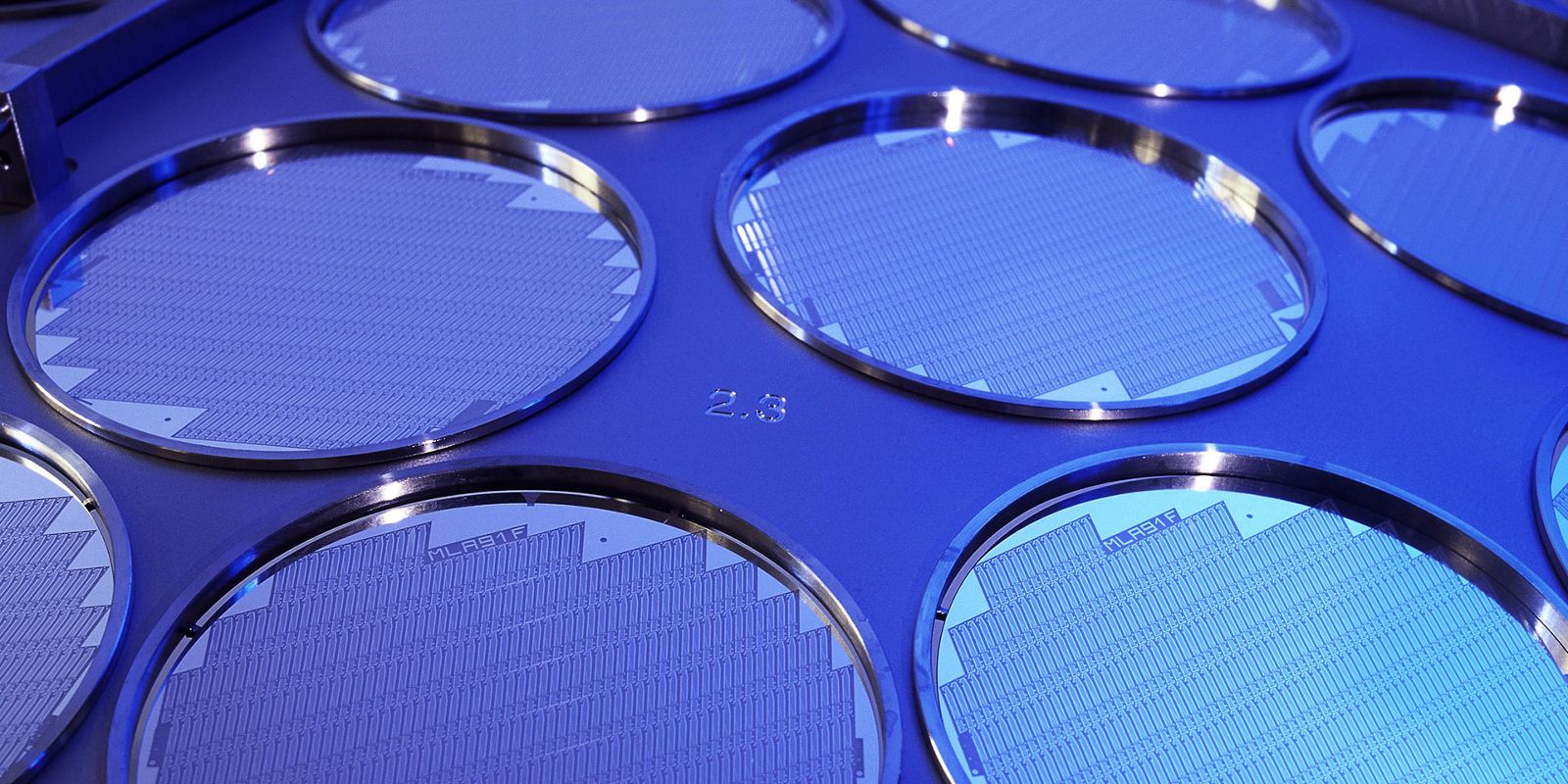

Because of their properties, compound semiconductors represent a special challenge in manufacturing. That's why in the past they were only used for extreme and marginal applications. Meanwhile, they are now finding their place in our everyday lives. Whether LEDs, laser diodes, or power semiconductors, they now form the functional foundation for computers, telephones, and tablets, cars, televisions, and networks. Compound semiconductors therefore make an essential contribution to our modern lives: they help us to transmit energy, perform calculations, or to get from one place to another.

Our molybdenum and tungsten materials as well as their alloys are essential for the manufacturing of many compound semiconductor elements. Our metals are used in most of the major compound semiconductor production facilities worldwide. We supply components for the daily operation of your facilities and for the development of next-generation process tools. Our products cover the range of compound semiconductor front end process tools. From MOCVD layers to etching and trimming, ion milling, deposition and coating, all of our products have one thing in common – they meet the highest quality standards.

With 100 years of experience in powder metallurgical manufacturing processes and decades of experience in the semiconductor industry, you can count on us as a capable and reliable partner. Our materials scientists and engineers will work together with you to find innovative and customized solutions for your application.